How does a servo motor work?

How does a servo motor work?

Mar 05, 2024

Servo motor refers to the engine that controls the operation of mechanical components in the servo system. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as an actuator and has the characteristics of small electromechanical time constant, high linearity, starting voltage, etc. It can convert the received electrical signal Converted into angular displacement or angular velocity output on the motor shaft. Divided into two categories: DC and AC servo motors.

Working principle

A servo mechanism is an automatic control system that enables the output controlled quantities such as the position, orientation, and state of an object to follow any changes in the input target (or given value). The servo mainly relies on pulses for positioning. Basically, it can be understood that when the servo motor receives a pulse, it will rotate at an angle corresponding to the pulse, thereby achieving displacement. Because the servo motor itself has the function of emitting pulses, every time the servo motor rotates through an angle, it will emit a corresponding number of pulses. In this way, it forms a response to the pulses received by the servo motor, or is called a closed loop. In this way, the system will know How many pulses are sent to the servo motor and how many pulses are received back at the same time. In this way, the rotation of the motor can be controlled very accurately, thereby achieving precise positioning, which can reach 0.001mm.

Classification of servo motors

Servo motors can be divided into DC servo motors and AC servo motors.

DC servo motor

The basic structure of a DC servo is similar to that of a general DC motor. Motor speed n=E/K1j=(Ua-IaRa)/K1j, where E is the armature counter electromotive force, K is a constant, j is the magnetic flux of each pole, Ua and Ia are the armature voltage and armature current, Ra is The armature resistance, changing Ua or changing φ, can control the speed of the DC servo motor, but the method of controlling the armature voltage is generally used. In the permanent magnet DC servo motor, the excitation winding is replaced by a permanent magnet, and the magnetic flux φ is constant. . DC servo motor has good linear adjustment characteristics and fast time response.

However, AC servo motors have limitations in brush commutation and speed, have additional resistance, and produce wear particles.

AC servo motor

The basic structure of an AC servo motor is similar to an AC induction motor (asynchronous motor). There are two excitation windings Wf and control windings WcoWf with a phase space displacement of 90° electrical angle on the stator. They are connected to a constant AC voltage and use the changes in the AC voltage or phase applied to Wc to control the operation of the motor.

AC servo motors have the characteristics of stable operation, good controllability, fast response, high sensitivity, and strict nonlinearity indicators of mechanical characteristics and adjustment characteristics (required to be less than 10% to 15% and less than 15% to 25% respectively).

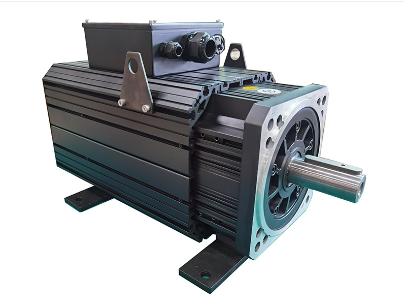

Shungrui Motor, a subsidiary of Shunge, specializes in high-power and high-torque permanent magnet AC servo motors. It currently has two series, 18 and 25, which can meet the needs of most customers.

We can also provide motor customization services according to customer needs, which is very cost-effective. Welcome to contact us for consultation.

Read More

How does a servo motor work?

How does a servo motor work?