Selecting of steel

Selecting of steel

ASTM standard silicon steel coils providing core power for high-efficiency electrical equipment

ASTM standard silicon steel coils providing core power for high-efficiency electrical equipment

Low-iron-loss motor laminated silicon steel helps new energy vehicles achieve a leap in performance.

Low-iron-loss motor laminated silicon steel helps new energy vehicles achieve a leap in performance.

Application scenarios of silicon steel for new energy vehicles

Application scenarios of silicon steel for new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

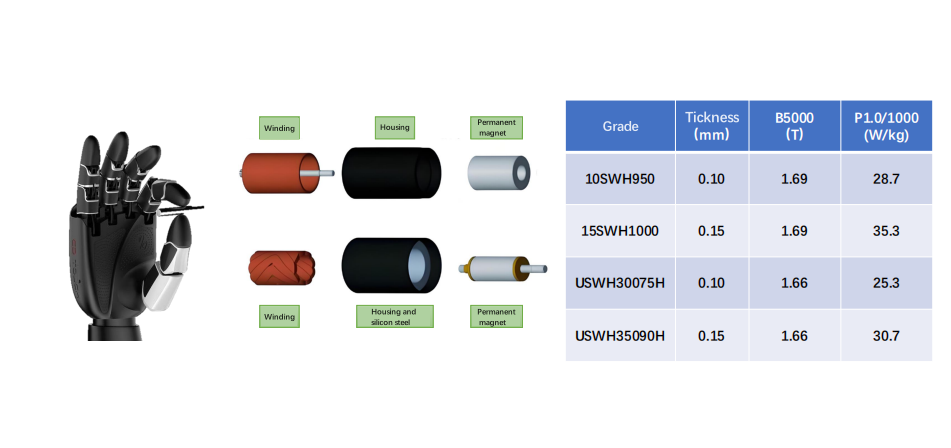

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

What are the advantages of using ultra-thin silicon steel in axial cores

What are the advantages of using ultra-thin silicon steel in axial cores

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

Why Pursue "Ultra-thin" Silicon Steel?

Why Pursue "Ultra-thin" Silicon Steel?

Why pursue ultra-thin non-oriented silicon steel?What are the key advantages of this design?

Why pursue ultra-thin non-oriented silicon steel?What are the key advantages of this design?

We will contact you as soon as possible

Hi! Click one of our members below to chat on