Motors are designed to provide precise control over speed and direction, making them ideal for a wide range of applications. Using the suitable servo motor to develop an energy-saving solution for production, the power saving could reach at least 30%.

A few factors are needed to take into consideration when it comes to customize your own servo motors:

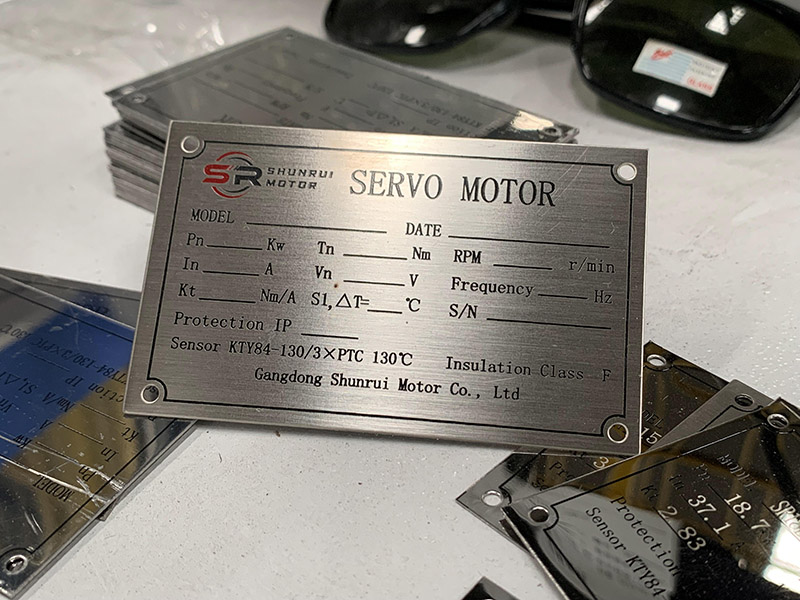

Servo Motor Nameplate

1. Determine the torque, power and speed requirements of your application. Determine the voltage and current requirements for the servo motor. Decide on the rotor type: Permanent magnet surface mount rotor or Permanent magnet embedded rotor. Choose a motor that can be supplied with the appropriate power source. This will help narrow down the selection of servo motors that are powerful enough to handle the workload.

2. Consider the environment or the using occasion such as equipment where the servo motor will be used. Operating temperature, humidity, and other environmental factors should be taken into consideration. Some motors are optimized for harsh industrial environments, while others are designed for more delicate laboratory settings.

3. Since protection level of servo motors is important, choose those with robust construction and high reliability. The motor's durability and performance are important factors to consider, especially if it is used in demanding applications that require it to operate continuously under heavy loads.

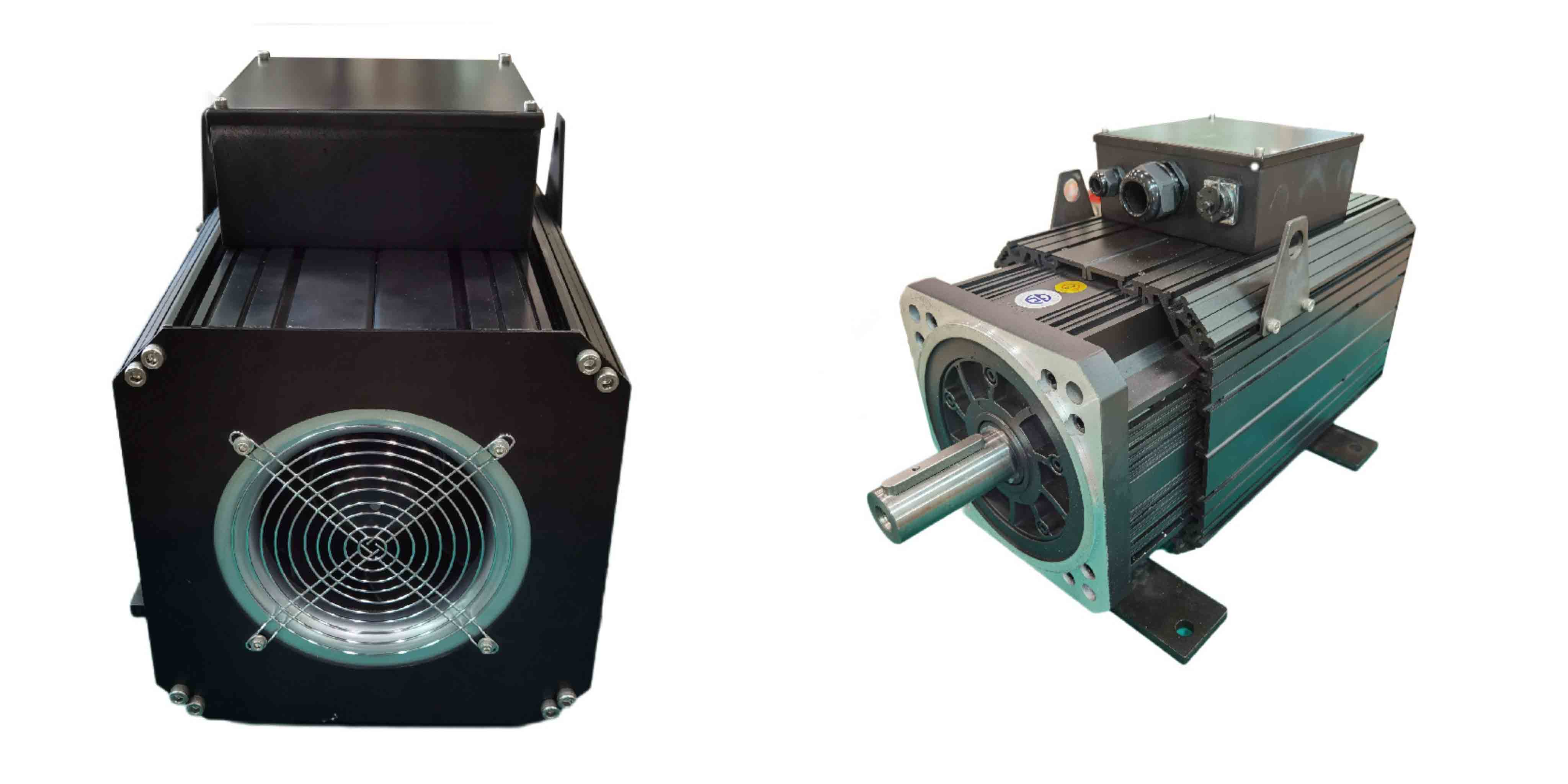

4. Decide on the cooling method: air cooling/ liquid cooling/ natural cooling.

5. Evaluate the control mechanisms and feedback systems of different servo motor options: Whether encoder is needed and which encoder type is appropriate? Whether matching driver of the servo motor is needed? resolver or other feedback device to control the position of the servo motor.Some motors have built-in motion control capabilities that can simplify system integration and improve performance.

6. Check the compatibility with the other components of your system. The servo motor you select must be compatible with the rest of your system, including the controller, power supply, and cabling.

7. Confirm on the size and weight: Consider the size and weight of the servo motor for your application. Choose a servo motor size that will fit within the available space.

8. Determine the cost of different servo motors and compare them against other factors such as performance, reliability, and compatibility. Remember that the cheapest option may not necessarily be the best option for your production needs.

We will contact you as soon as possible

Hi! Click one of our members below to chat on