What is silicon steel used for?

What is silicon steel used for?

Nov 04, 2023

In the previous article, we know that silicon steel can be divided into oriented silicon steel and non-oriented silicon steel, which have different uses.

So what are the uses of these two similar silicon steels? Today’s article will tell you.

Use of Oriented Silicon Steel

Oriented silicon steel, or CRGO, is an important soft magnetic material in the military and electronic industries, mainly used as high-frequency transformers, high-power magnetic amplifiers, pulse generators, general yoke coils, inductors, storage and memory components, switches and control components, magnetic shielding, and transformers operating under vibration and radiation conditions.

Compared with other materials such as ferrite and amorphous materials, the iron core can be made very small due to the high saturation magnetic induction and high magnetic permeability of the 3% Si-Fe thin strip.

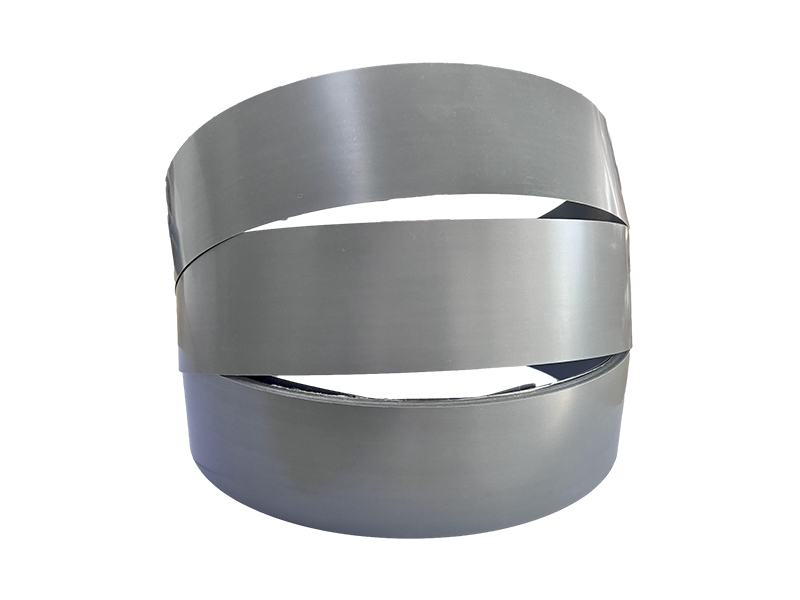

Because it is a cold-rolled strip, it has a smooth surface, small differences between the same plates, good plate shape, and good processing performance. It can be made into iron cores of various shapes and specifications such as CD type, ring type, and rectangular type. It has a wide range of applicationsand wide frequency range (50H-20KH).

Use of Non-oriented Silicon Steel

Non-oriented silicon steel is mainly used in motors:

Gap motors (water pumps) mainly use cold-rolled, non-oriented, uncoated silicon steel.

Motors for electric welding machines are divided into DC motors and AC motors. DC motors can use uncoated cold-rolled silicon steel, and AC motors mainly use coated 600 non-oriented silicon steel.

Air compressor, and pneumatic pump motors can also use uncoated cold-rolled silicon steel.

The micro motors used in small household appliances mainly use non-oriented 470. Most of the motor used in CNC machine tools is 470. Motors for air conditioning compressors mainly use 600, 800, 1000, and 1300 silicon steel.

Air compressor

Silicon steel occupies a very important position in electrification construction. In a sense, the amount of silicon steel sheets used in a country can measure the degree of electrification in the country. Therefore, in the long run, electrical steel has great development prospects.

Have any questions or requirements about silicon/electrical steel, feel free to contact us.

Read More

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

What is silicon steel used for?

What is silicon steel used for?

What is silicon steel used for?

What is silicon steel used for?