The Role of Laminated Iron Cores: Enhancing Electrical Machinery Efficiency

The Role of Laminated Iron Cores: Enhancing Electrical Machinery Efficiency

Jun 03, 2025

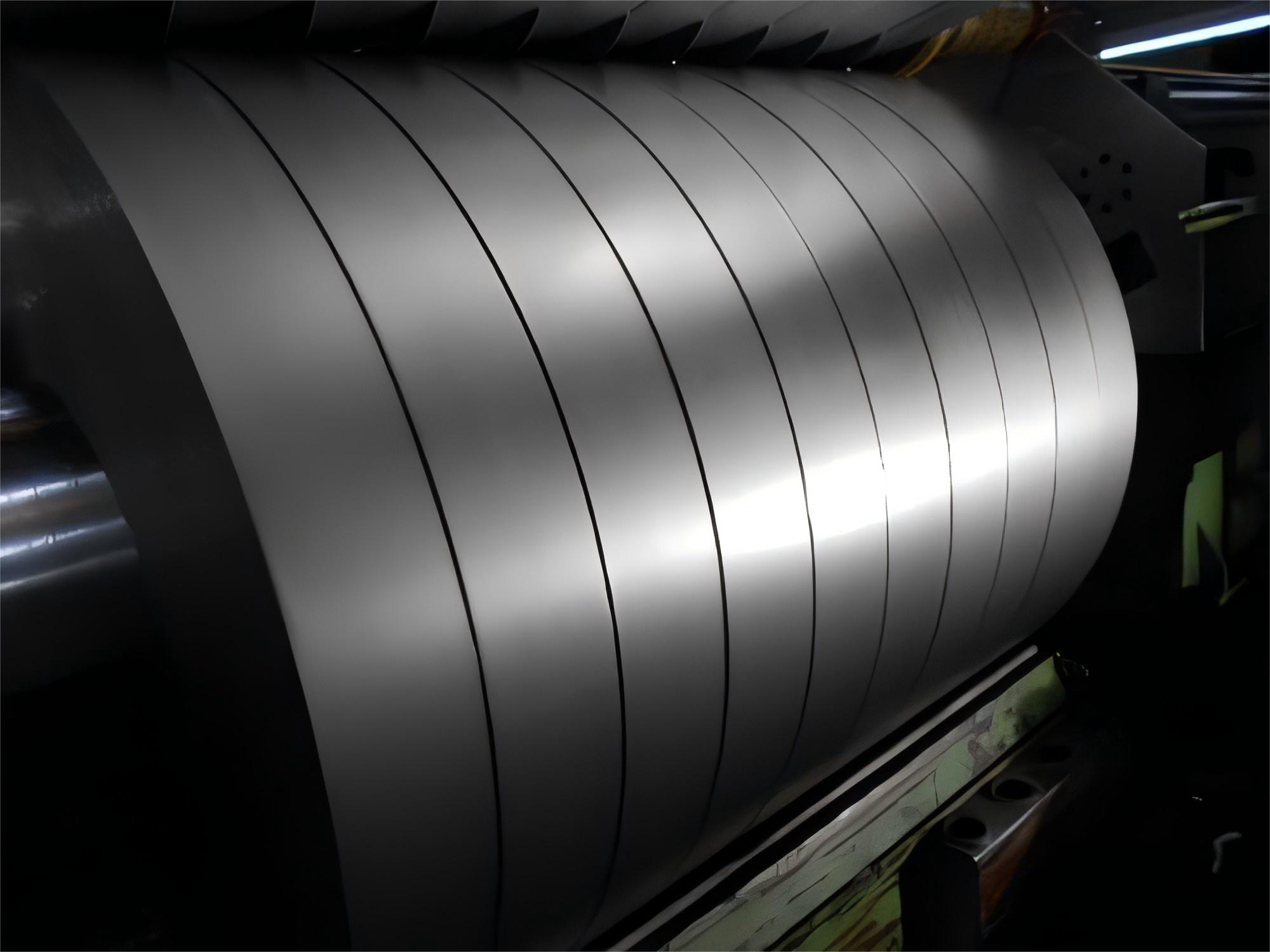

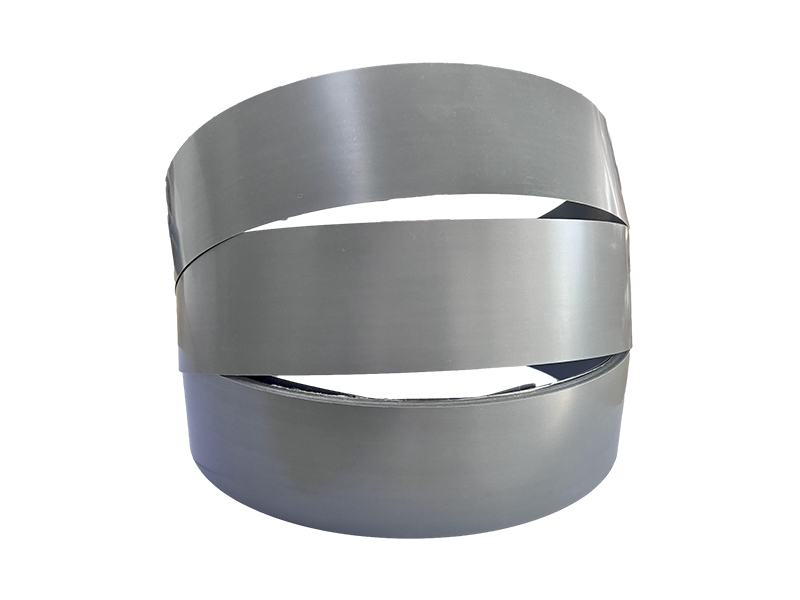

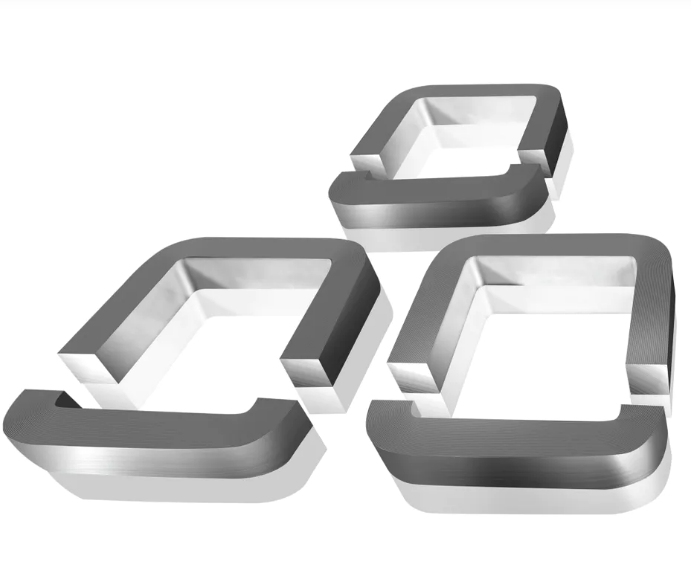

Laminated iron cores play a crucial role in various electrical devices, significantly influencing equipment performance and efficiency. Constructed by stacking thin silicon steel or iron alloy sheets with insulation between layers, this unique structural design equips laminated iron cores with multiple functions, making them indispensable in transformers, motors, inductors, and other devices.

Reducing Eddy Current Losses Significantly

Based on the principle of electromagnetic induction, when an iron core is exposed to an alternating magnetic field, it generates an induced electromotive force, forming closed loops inside the core, resulting in eddy currents. Eddy currents cause the core to heat up, leading to energy loss and reduced device efficiency. By dividing the iron core into numerous thin sheets, laminated iron cores increase the resistance path for eddy currents. Due to the extreme thinness of each sheet, the eddy current flow is greatly reduced under the same induced electromotive force. For instance, in transformers, using laminated iron cores effectively reduces eddy current losses, enhancing electric energy transmission efficiency. Studies indicate that compared to solid iron cores, laminated iron cores can decrease transformer eddy current losses by orders of magnitude, significantly improving energy conservation during power transmission.

Optimizing Magnetic Performance Effectively

Materials like silicon steel inherently possess high magnetic permeability; however, in an alternating magnetic field, hysteresis can lead to energy loss. The laminated structure smoothens the flipping of magnetic domains in the core during magnetic field changes, reducing hysteresis losses. Additionally, the insulation layers between each sheet prevent lateral diffusion of magnetic flux, concentrating flux flow along the core's axial direction, enhancing magnetic permeability of the magnetic circuit, and strengthening electromagnetic induction effects. In motors, superior magnetic performance allows the motor to generate a more stable and stronger magnetic field during operation, increasing the motor's output torque and operational efficiency, ensuring the motor runs efficiently and reliably.

Enhancing Heat Dissipation Capability

The gaps between laminated sheets form natural heat dissipation channels. When equipment generates heat during operation, this heat dissipates more effectively through these gaps, helping lower the core's temperature, preventing performance degradation or damage due to overheating. For instance, in large generators, the excellent heat dissipation performance of laminated iron cores ensures that the generator maintains a stable operating temperature during extended high-load operations, enhancing the generator's reliability and lifespan.

Laminated iron cores, by reducing eddy current losses, optimizing magnetic performance, and enhancing heat dissipation capabilities, play an irreplaceable role in various electrical devices such as transformers, motors, and inductors. Their significance lies in improving equipment efficiency, performance, stability, as well as in achieving energy-saving and emission reduction goals. With ongoing technological advancements, the materials and manufacturing processes of laminated iron cores continue to evolve, promising to unleash even greater value across diverse fields in the future.

Read More

The Role of Laminated Iron Cores: Enhancing Electrical Machinery Efficiency

The Role of Laminated Iron Cores: Enhancing Electrical Machinery Efficiency

Understanding Different Grades of Oriented Silicon Steel for Transformer Cores

Understanding Different Grades of Oriented Silicon Steel for Transformer Cores

CRGO Silicon Steel for Efficient Power Transmission

CRGO Silicon Steel for Efficient Power Transmission

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

Why is lamination used in the core of a transformer?

Why is lamination used in the core of a transformer?

The Significance of Lamination in Transformer Cores

The Significance of Lamination in Transformer Cores

Transformer Cores: Enhancing Efficiency and Performance with Silicon Steel

Transformer Cores: Enhancing Efficiency and Performance with Silicon Steel

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

TEN differences between dry-type transformers and oil-immersed transformers

TEN differences between dry-type transformers and oil-immersed transformers

What is the difference between adding or not adding an iron core to the transformer?

What is the difference between adding or not adding an iron core to the transformer?