Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

May 27, 2024

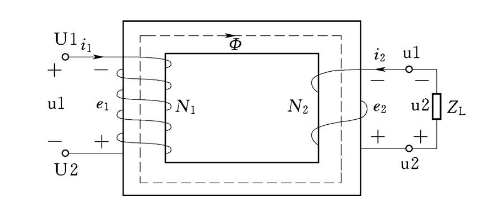

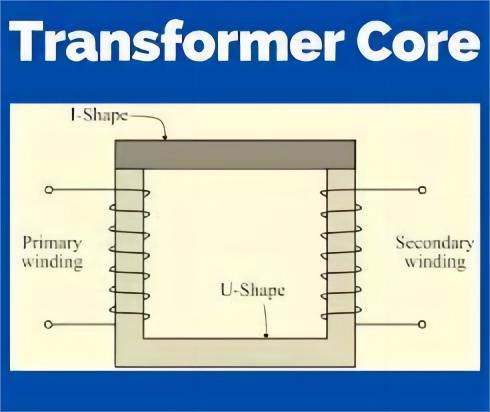

Transformers play a vital role in electrical power systems, enabling efficient transmission and distribution of electricity. At the heart of every transformer lies the core, a crucial component that ensures the smooth conversion of electrical energy between different voltage levels. This article will explore two commonly used core materials in transformers, CRGO (Cold-Rolled Grain Oriented) and CRNGO (Cold-Rolled Non-Grain Oriented), highlighting their characteristics, advantages, and application scenarios.

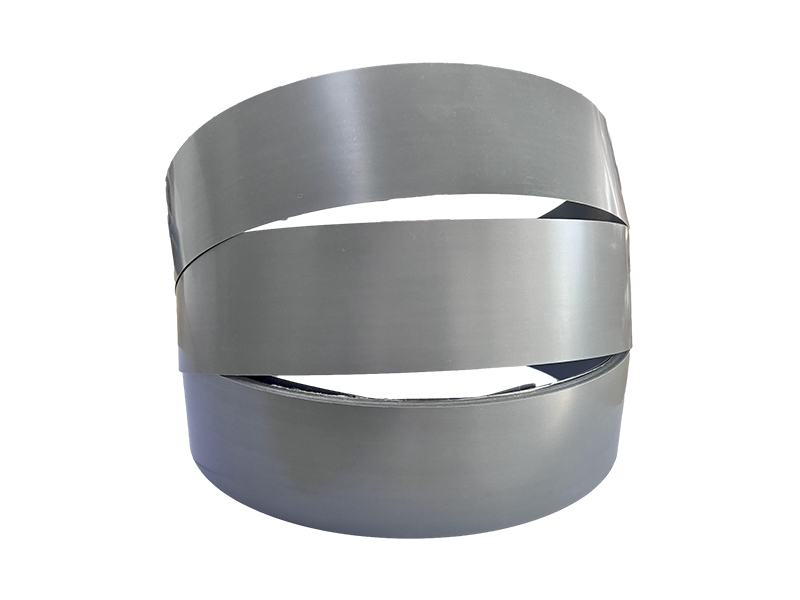

CRGO Transformer Cores

CRGO cores are widely employed in power transformers, where high efficiency and low core losses are crucial. The production process involves cold-rolling a silicon steel strip to align the grains in the crystal lattice structure, resulting in excellent magnetic properties. CRGO cores exhibit the following key features:

Reduced Core Losses: The grain-oriented structure of CRGO cores minimizes magnetic hysteresis and eddy current losses, leading to superior energy efficiency and reduced heat generation.

High Magnetic Permeability: CRGO cores exhibit high magnetic permeability, enabling efficient magnetization and demagnetization cycles during power conversion processes, thus enhancing overall transformer performance.

Low Magnetostriction: Magnetostriction is the phenomenon where a material changes shape under the influence of a magnetic field. CRGO cores have low magnetostriction, reducing mechanical stress on the transformer and minimizing audible noise.

Application Scenarios: CRGO cores are commonly used in large power transformers, distribution transformers, and high-power applications due to their excellent energy conversion efficiency and performance stability over a wide range of operating conditions.

CRNGO Transformer Cores

CRNGO cores are predominantly employed in low and medium-power transformers, along with various electrical machines, such as motors and generators. Unlike CRGO cores, CRNGO cores do not possess grain-oriented crystal structures. Their key characteristics include:

Enhanced Permeability: Although lower than CRGO cores, CRNGO cores still exhibit reasonable magnetic permeability, making them suitable for applications requiring moderate power conversion efficiency.

Lower Production Costs: The absence of grain orientation in CRNGO cores simplifies the manufacturing process, resulting in reduced production costs compared to CRGO cores.

Wide Variety of Shapes: CRNGO cores can be easily tailored into different shapes and sizes, allowing for design flexibility and customization to meet specific application requirements.

Application Scenarios: CRNGO cores find extensive use in lower-power transformers, small power supplies, electric vehicles, and other applications demanding cost-effectiveness and optimal performance within a limited operating range.

Selecting the appropriate transformer core material is critical to achieving optimal performance and efficiency in various electrical applications. CRGO cores excel in high-power transformers, where minimal losses and excellent energy conversion are paramount. On the other hand, CRNGO cores find applications in low-to-medium-power transformers, motors, and generators, offering a balance between performance and cost-effectiveness. Understanding the characteristics of these transformative core materials is essential for designing reliable and efficient electrical systems.

As a leading transformer manufacturer, our company specializes in producing high-quality transformer cores tailored to meet the diverse needs of our customers. Whether you require CRGO or CRNGO cores, we are committed to delivering exceptional products that optimize performance and contribute to the advancement of electrical power systems.

We welcome you to contact us for any transformer core requirements or further inquiries.

Read More

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

Unveiling the Magnetic Marvel: The Fascinating World of Orientation Silicon Steel

The Significance of Lamination in Transformer Cores

The Significance of Lamination in Transformer Cores

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

What is the difference between adding or not adding an iron core to the transformer?

What is the difference between adding or not adding an iron core to the transformer?

How does a transformer achieve voltage transformation?

How does a transformer achieve voltage transformation?

What is a core in the transformer?

What is a core in the transformer?