Overview of Steel Usage in the Electric Vehicle Industry

Currently, the electric vehicle (EV) industry is experiencing rapid growth. Steel plays a crucial role in this wave of development, serving as an important driving force for the industry's advancement. Let's take a closer look at the specific types of steel used in electric vehicles.

Analysis of Commonly Used Steel Types in Electric Vehicles

High-strength steel is vital in the construction of electric vehicle body structures. It significantly enhances vehicle safety by effectively absorbing energy and protecting passengers during collisions. Additionally, high-strength steel facilitates lightweight vehicle design, reducing energy consumption and improving range. Common types include dual-phase steel (DP) and transformation-induced plasticity steel (TRIP), among others.

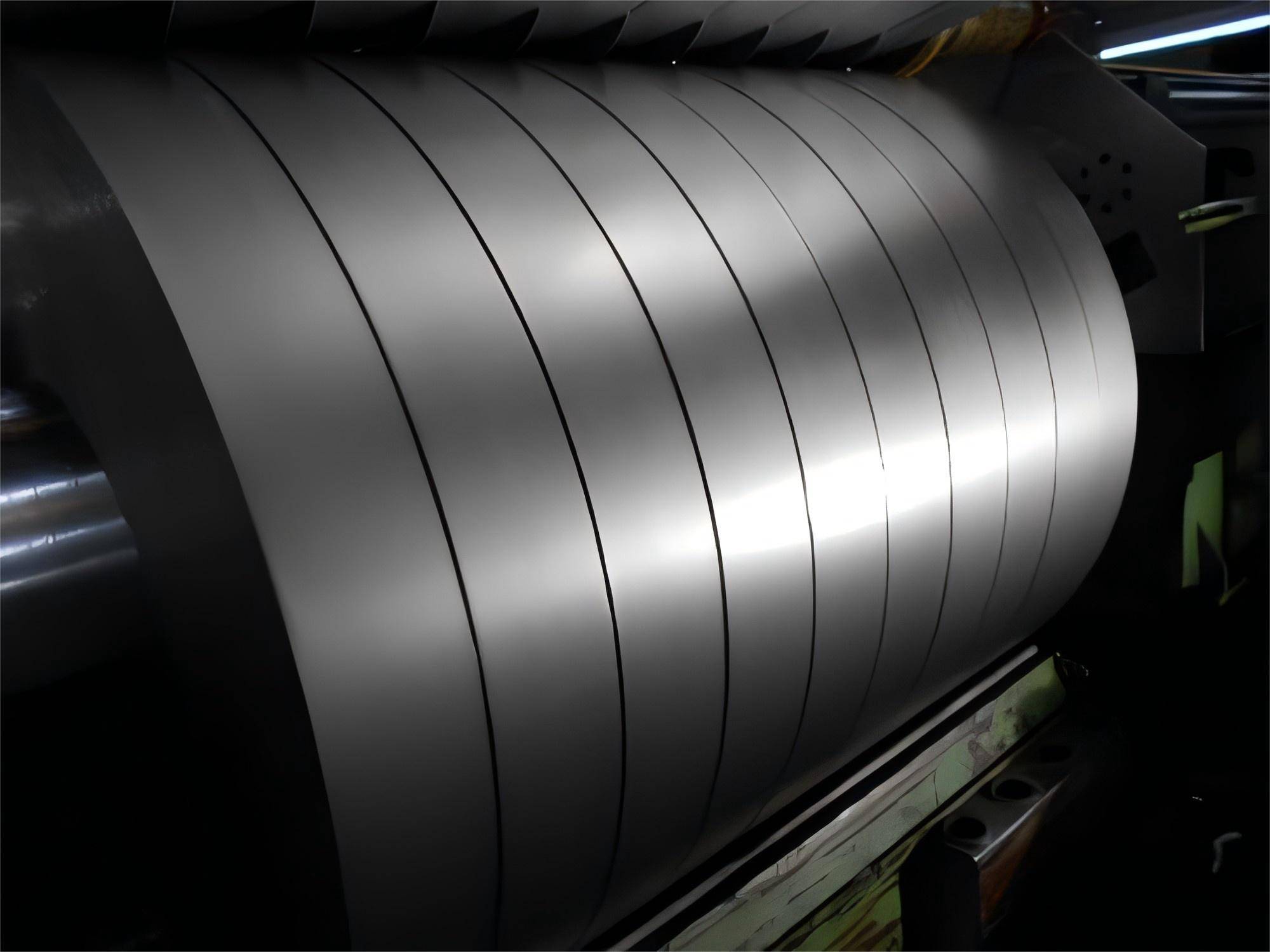

In electric vehicles, electrical steel, also known as silicon steel, is the key material that determines motor performance. It reduces iron losses in motors, thereby increasing motor efficiency and power density, ensuring more efficient motor operation and enhancing overall vehicle performance.

New Energy Silicon Steel: The "Superheart" of Motors

Represented by grades such as 20W1200, 27W1500, 30W1600, and 35W1900, new energy silicon steel exhibits significant advantages over conventional steel in terms of magnetic permeability and iron loss characteristics. Its high magnetic permeability enables motors to convert electrical energy into mechanical energy more efficiently, while its low iron loss reduces energy dissipation.

These performance advantages of new energy silicon steel effectively enhance the power, economy, and durability of electric vehicles. Improved power output, extended driving range, and reduced energy consumption provide users with a better driving experience.

Applications of New Energy Silicon Steel in the Electric Vehicle Industry

Among various electric vehicle brands, Tesla's Model 3 Long Range serves as a typical example. Its permanent magnet synchronous motor, equipped with specific grades of new energy silicon steel, benefits from the remarkable magnetic permeability of this material. As a result, the vehicle achieves exceptional acceleration, requiring only 4.4 seconds to go from 0 to 100 km/h, thanks to the powerful motor output. Moreover, the low iron loss characteristic of new energy silicon steel significantly reduces energy dissipation during motor operation, leading to an increased driving range of up to 448 kilometers according to EPA standards, providing users with an excellent driving experience.

Leading domestic new energy vehicle manufacturer, BYD, also adopts high-quality new energy silicon steel in its Han EV model. Through optimized motor design and appropriate selection of new energy silicon steel, the BYD Han EV achieves efficient power output. In real-world testing, the vehicle's energy consumption is reduced by approximately 10% to 15% compared to similar models without high-performance new energy silicon steel, significantly improving energy utilization. Moreover, during durability testing, motors featuring new energy silicon steel demonstrate excellent stability, maintaining consistent performance even after prolonged high-intensity operation, ensuring vehicle reliability throughout long-term use.

SHUNGE STEEL: Pioneer in the New Energy Silicon Steel Industry

SHUNGE STEEL has established deep partnerships with well-known automakers like BYD. By providing high-quality new energy silicon steel and automotive steel to these companies, SHUNGE STEEL has played a vital role in improving vehicle performance and helping automakers create more competitive products.

The collaboration between SHUNGE STEEL and automakers has significantly promoted technological innovation in new energy silicon steel, driven the improvement of industry standards, and effectively propelled the development of the entire electric vehicle industry, leading the industry to new heights.

Future Outlook: Symbiotic Development of Steel and Electric Vehicles

Looking ahead, steel will continue to innovate and advance in the electric vehicle industry. Ongoing research and development will lead to the introduction of new steel types, and the application areas of steel will further expand. The symbiotic development of steel and the electric vehicle industry will shape a greener and more efficient future of transportation.

We will contact you as soon as possible

Hi! Click one of our members below to chat on