EI core laminations, composed of pure steel with a silicon content ranging from 0.5% to 5.5%, are widely employed in electrical and electronic equipment as low-frequency transformer cores. They enhance the magnetic properties essential for the functioning of transformers and motors. By transferring energy from the primary winding to the secondary winding, they aid in effective energy discharge. Different grades of laminations are available, categorized based on their silicon content, allowing for suitable selection according to the specific characteristics and requirements of the equipment and devices in use.

Product Origin :

CHINAShipping Port :

GUANGZHOU/SHENZHENPayment :

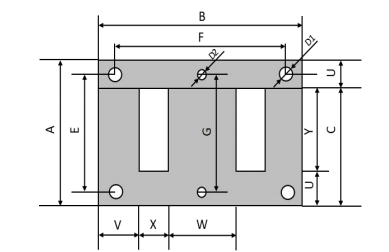

T/T at sightEI laminations, also known as electrical steel laminations, are widely used in various electrical and electronic applications. These laminations are made from thin layers of electrical steel, typically consisting of silicon, to enhance their magnetic properties. The EI shape of the laminations refers to the core's configuration, which consists of two E-shaped elements joined together with a central I-shaped element.

|

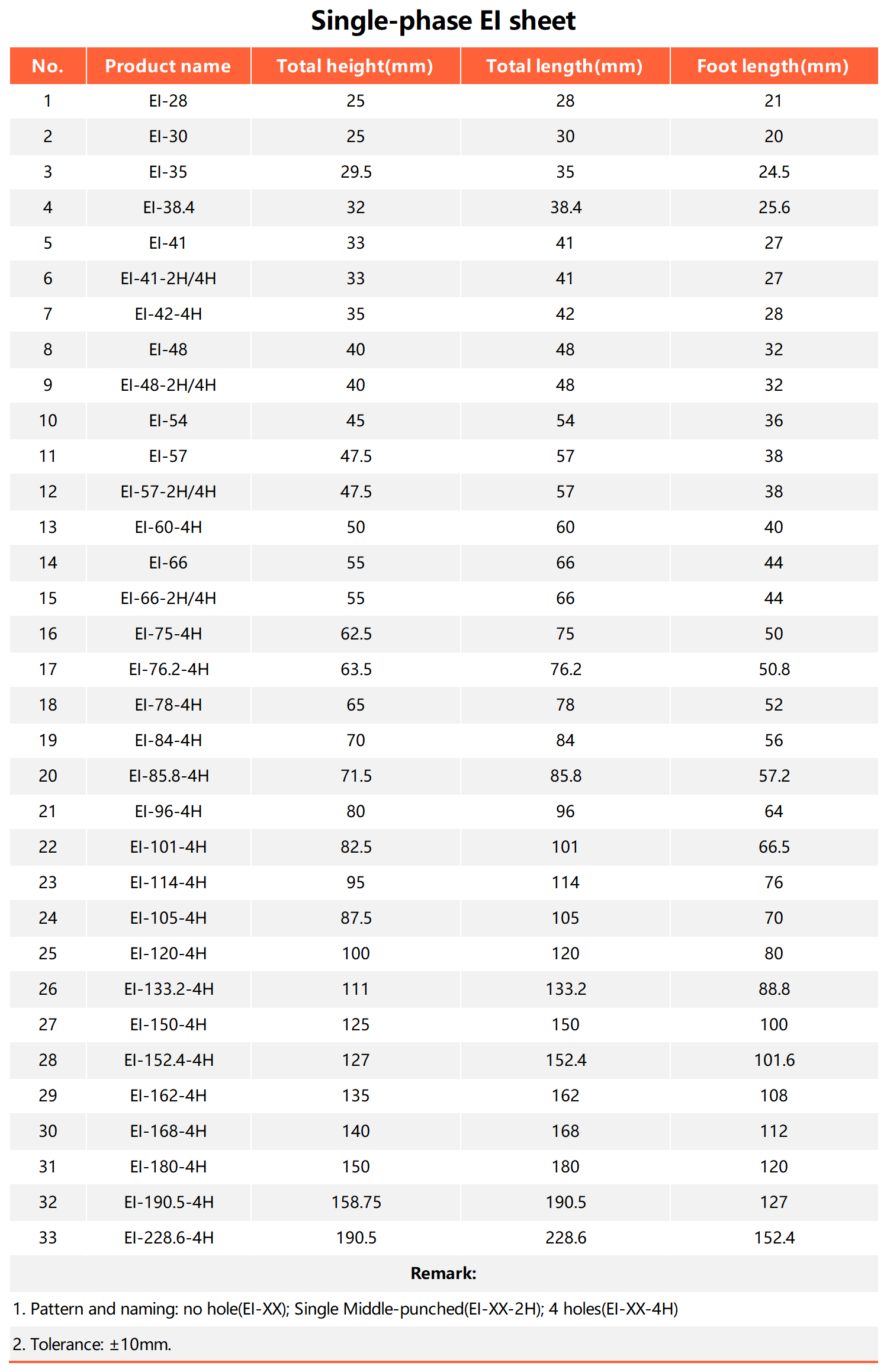

Silicon Steel E-I Lamination Material: Grain Oriented(0.35mm) and Non Oriented(0.5mm) Electrical Steel Sheets |

|

These laminations are available in different grades, varying in silicon content and thickness, to suit specific applications and requirements. Higher silicon content provides better magnetic saturation, while thinner laminations minimize energy losses. The selection of the appropriate grade depends on factors such as operating frequency, voltage, and core size.

EI laminations find extensive use in transformers, motors, generators, and electromagnetic devices. They play a crucial role in these devices by providing a magnetic path for efficient energy transfer. The laminations help reduce energy losses caused by eddy currents and hysteresis, thus improving the overall efficiency of the equipment.

These laminations are available in different grades, varying in silicon content and thickness, to suit specific applications and requirements. Higher silicon content provides better magnetic saturation, while thinner laminations minimize energy losses. The selection of the appropriate grade depends on factors such as operating frequency, voltage, and core size.

|

|

|

EI laminations offer several advantages, including low core loss, high magnetic permeability, and excellent thermal stability. They also contribute to reduced noise and vibration levels in the equipment. Additionally, the modular design of EI laminations allows for easy assembly, maintenance, and customization.

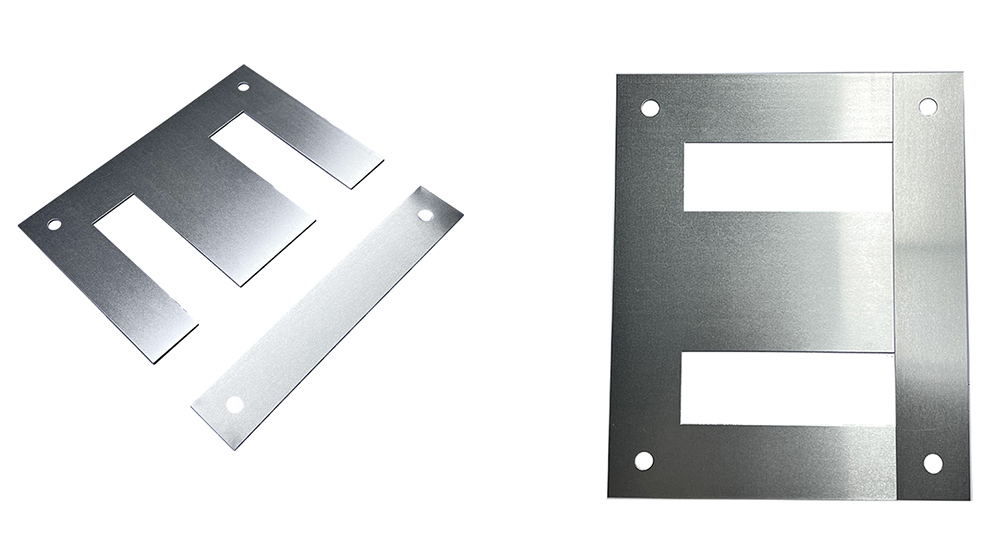

EI lamination punching line

Annealing furnace

Final product - EI silicon steel sheet

Tested and certified by RoHS

We will contact you as soon as possible

Hi! Click one of our members below to chat on