Why Transformer Cores Use Silicon Steel Laminations

Why Transformer Cores Use Silicon Steel Laminations

Mar 20, 2024

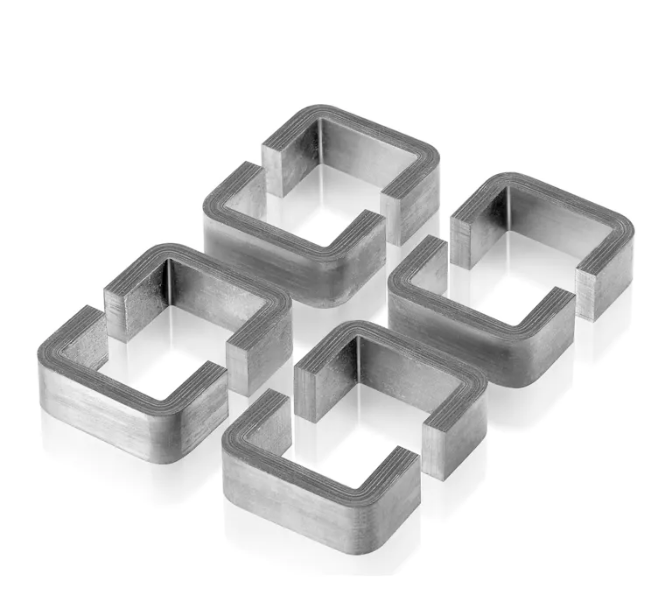

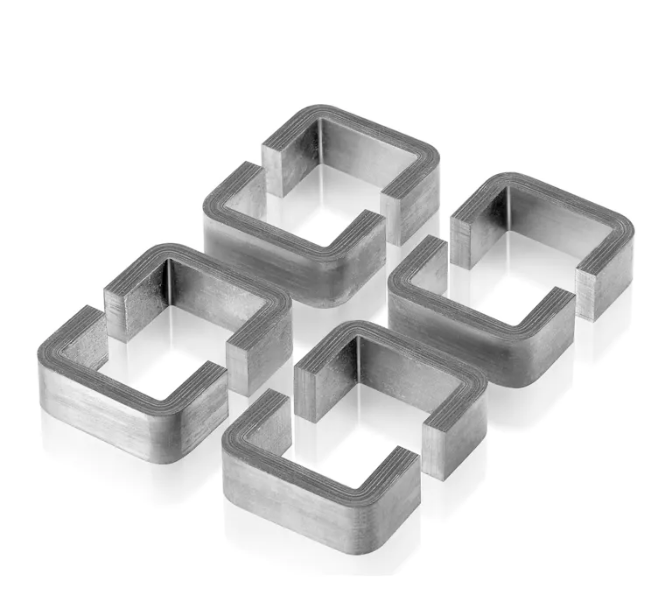

Transformer cores play a crucial role in the efficient and reliable operation of transformers, which are essential devices in power distribution systems. These cores are typically made of laminated silicon steel sheets known as silicon steel laminations. But have you ever wondered why silicon steel is the preferred material for transformer cores? Let's dive into the reasons behind this choice.

1. Magnetic Properties:

Silicon steel possesses excellent magnetic properties that make it an ideal material for transformer cores. It exhibits low core losses, also known as hysteresis losses, which occur when the magnetic field in the core repeatedly reverses direction during the input and output cycles of a transformer. The low hysteresis losses of silicon steel help minimize energy wastage and improve overall transformer efficiency.

2. High Permeability:

Permeability refers to a material's ability to allow the magnetic field to pass through it. Silicon steel exhibits high permeability, which means it can efficiently channel and concentrate the magnetic flux within the core. This property ensures effective magnetic coupling between the primary and secondary windings of the transformer, resulting in optimal energy transfer.

3. Electrical Resistance:

Another critical characteristic of silicon steel is its high electrical resistance, which helps mitigate eddy current losses. Eddy currents are induced within the core due to the alternating magnetic field, leading to heat generation and energy losses. However, by using laminations, the silicon steel core effectively reduces the path for eddy currents, minimizing their detrimental effects and enhancing transformer performance.

4. Preservation of Core Integrity:

Transformers operate at varying frequencies, typically in the range of 50-60 Hz. This alternating magnetic field can generate significant heat, which can impact the core's structural integrity. Silicon steel, with its high magnetic saturation and low magnetostriction properties, can withstand these temperature variations and maintain the core's shape and performance over time.

5. Cost-Effectiveness:

Silicon steel is a cost-effective material widely available in the market, making it a practical choice for transformer cores. Its favorable magnetic properties and widespread usage also contribute to its affordability.

In conclusion, the use of silicon steel laminations in transformer cores is driven by its exceptional magnetic properties, high permeability, low core losses, and electrical resistance. These features make it the preferred material for ensuring efficient energy transfer, minimizing losses, and enhancing the overall performance and reliability of transformers.

Read More

What are the characteristics of transformer laminated core?

What are the characteristics of transformer laminated core?

Why Transformer Cores Use Silicon Steel Laminations

Why Transformer Cores Use Silicon Steel Laminations