Cold rolled non grain oriented steel has stable magnetic properties in all directions and shows excellent performance in high lamination. CRNGO steel is frequently used in motors, generators and cores of silicon steel transformers and many other promising industries.

MOQ :

10TPayment :

T/T LC at sightProduct Origin :

ChinaShipping Port :

Guangzhou/ ShenzhenNon grain oriented silicon steel is generally applied to manufacture high laminated core transformer and industrial large machines. Specialized in professional products and processing service for almost 15 years, Shunge could provide cold-rolled non-grain oriented silicon steel in forms of coils, sheets, plates and strips, etc. and personalized steel processing service of decoiling, slitting and shearing, etc.

Product Description (For reference)

|

Product Name |

Cold Rolled Grain NON-Oriented Silicon Steel |

|

Thickness |

0.20mm-0.50mm |

|

Width |

20mm-1250mm or as required |

|

Length |

Coil Or As Required |

|

Technique |

Cold Rolled |

|

Surface Treatment |

Coated |

Advantages

1. low iron loss

2. high magnetic induction

3. uniform thickness

4. good punchability

5. small thickness deviation

6. stable performance

7. high lamination coefficient

8. outstanding welding performance

9. good corrosion resistance

10. good freon resistance

Product Series

|

Product series |

Main specification |

Features |

|

General series |

0.35mm 0.50mm 0.65mm |

Similar excellent product performance benchmarking with leading companies at home and abroad |

|

High efficient series |

0.35mm 0.50mm |

Lower core loss and higher magnetic induction than concentional products |

|

Stress relief annealing series |

0.35mm 0.50mm |

Low core loss, high magnetic induction and good machinablity after annealing |

|

New energy vehicle series |

0.35mm 0.30mm 0.27mm 0.20mm |

Excellent electromagnetic performance under high frequancy |

Grade Table (For reference)

|

Type |

Thickness (mm) |

Shousteel |

NSC |

JFE |

TKS |

Posco |

NI&Sco |

AK |

|

General series |

0.35 |

35SW230 |

35H230 |

35JN230 |

M235-35A |

35PN230 |

|

|

|

35SW250 |

35H250 |

35JN250 |

M250-35A |

35PN250 |

2413 |

M-15 |

||

|

35SW270 |

35H270 |

35JN270 |

M270-35A |

35PN270 |

2412 |

M-19 |

||

|

35SW300 |

35H300 |

35JN300 |

M300-35A |

35PN300 |

2411 |

M-22/M-27 |

||

|

35SW360 |

35H360 |

35JN360 |

|

35PN360 |

|

|

||

|

35SW440 |

35H440 |

35JN440 |

|

35PN455 |

|

|

||

|

35SW550 |

|

|

|

35PN560 |

|

|

||

|

0.5 |

50SW230 |

50H230 |

50JN230 |

M230-50A |

50PN230 |

|

|

|

|

50SW250 |

50H250 |

50JN250 |

M250-50A |

50PN250 |

|

|

||

|

50SW270 |

50H270 |

50JN270 |

M270-50A |

50PN270 |

2414 |

|

||

|

50SW290 |

50H290 |

50JN290 |

M290-50A |

50PN290 |

2413 |

M-15 |

||

|

50SW310 |

50H310 |

50JN310 |

M310-50A |

50PN310 |

2412 |

M-19 |

||

|

50SW350 |

50H350 |

50JN350 |

M350-50A |

50PN350 |

|

M-22 |

||

|

50SW400 |

|

|

M400-65A |

50PN400 |

|

M-27/M-36 |

||

|

50SW470 |

50H470 |

50JN470 |

M470-50A |

50PN445 |

2214 |

|

||

|

50SW600 |

50H600 |

50JN600 |

M600-50A |

50PN595 |

2212 |

|

||

|

50SW700 |

50H700 |

50JN700 |

M700-50A |

50PN760 |

|

M-47 |

||

|

50SW800 |

50H800 |

50JN800 |

M800-50A |

50PN890 |

2011 |

|

||

|

50SW1000 |

50H1000 |

50JN1000 |

M940-50A |

50PN1015 |

|

|

||

|

50SW1300 |

50H1300 |

50JN1300 |

M1100-50A |

50PN1270 |

|

|

||

|

0.65 |

65SSW800 |

|

65JN800 |

M800-65A |

65PN890 |

|

M-47 |

|

|

65SW1000 |

|

65JN1000 |

M1000-65A |

65PN1015 |

|

|

||

|

65SW1300 |

|

65JN1300 |

M1300-65A |

65PN1270 |

|

|

||

|

High efficient series |

0.5 |

50SWH470 |

|

50JNE470 |

|

|

|

|

|

50SWH600 |

|

|

|

|

|

|

||

|

50SWH800 |

|

|

|

|

|

|

||

|

50SWH1000 |

|

|

|

|

|

|

||

|

Stress relief annealing series |

0.35 |

35SWR300 |

|

|

|

|

|

|

|

0.5 |

50SW350 |

|

50JNA350 |

|

|

|

|

|

|

New energy vehicle strip series |

0.3 |

30SW2700 |

|

|

|

|

|

|

|

0.27 |

27SW2300 |

|

|

|

|

|

|

|

|

0.2 |

20SW1500 |

20HTH1500 |

20JNEH1500 |

|

|

|

|

Typical Mechanical Properties

General Series

|

Grade |

Nominal Thickness (mm) |

Theoretical Density (kg/dm³) |

Yield Strength (N/mm²) |

Tensile Strength (N/mm²) |

Hardness (Hv1) |

Elongation (%) |

|

|

35SW230 |

0.35 |

7.60 |

430 |

525 |

214 |

10 |

|

|

35SW250 |

7.60 |

420 |

490 |

200 |

10 |

|

|

|

35SW300 |

7.65 |

370 |

500 |

185 |

25 |

|

|

|

35SW360 |

7.65 |

325 |

470 |

165 |

30 |

|

|

|

35SW440 |

7.70 |

280 |

425 |

150 |

30 |

|

|

|

35SW550 |

7.75 |

255 |

420 |

140 |

35 |

|

|

|

50SW250 |

0.5 |

7.60 |

430 |

530 |

220 |

15 |

|

|

50SW270 |

7.60 |

410 |

520 |

195 |

12 |

|

|

|

50SW290 |

7.60 |

410 |

520 |

195 |

12 |

|

|

|

50SW310 |

7.65 |

375 |

510 |

185 |

30 |

|

|

|

50SW350 |

7.65 |

370 |

510 |

185 |

35 |

|

|

|

50SW400 |

7.65 |

320 |

460 |

165 |

35 |

|

|

|

50SW470 |

7.75 |

250 |

410 |

135 |

35 |

|

|

|

50SW600 |

7.75 |

240 |

400 |

126 |

35 |

|

|

|

50SW700 |

7.80 |

220 |

379 |

113 |

37 |

|

|

|

50SW800 |

7.80 |

230 |

379 |

113 |

37 |

|

|

|

50SW1000 |

7.85 |

240 |

370 |

114 |

45 |

|

|

|

50SW1300 |

7.85 |

245 |

375 |

115 |

45 |

|

New Energy Vehicle Series

|

Grade |

Nominal Thickness (mm) |

Theoretical Density (kg/dm³) |

Yield Strength (N/mm²) |

Tensile Strength (N/mm²) |

Hardness (Hv1) |

Elongation (%) |

|

|

20SW1200 |

0.20 |

7.65 |

400 |

520 |

200 |

10 |

|

|

20SW1500 |

0.20 |

7.65 |

370 |

480 |

180 |

10 |

|

|

27SW1500 |

0.27 |

7.65 |

420 |

520 |

210 |

20 |

|

|

30SW1600 |

0.30 |

7.65 |

440 |

560 |

210 |

25 |

|

|

35SW1700 |

0.35 |

7.65 |

440 |

560 |

210 |

25 |

|

|

35SW1900 |

0.35 |

7.65 |

410 |

530 |

200 |

25 |

|

|

25SWH1400 |

0.25 |

7.65 |

410 |

530 |

200 |

20 |

|

|

27SWH1400 |

0.27 |

7.65 |

410 |

530 |

200 |

20 |

|

|

30SWH1500 |

0.30 |

7.65 |

410 |

530 |

200 |

25 |

|

|

35SWH1900 |

0.35 |

7.65 |

370 |

510 |

180 |

25 |

|

|

35SWYS600 |

0.35 |

7.65 |

620 |

660 |

220 |

15 |

|

Coating Types

|

Coating Code |

Coating Type |

Coating Thickness |

Application |

Heat Resistance |

Insulation Resistance |

Stamping Ability |

Lamination Factor |

Weldability |

|

M1 |

Cr-free environmental friendly coating |

0.4 - 2μm |

General Coating |

In non-oxidation environment the coating is normal through 750°C stress relieving annealing. |

good |

very good |

high |

very good |

|

M4 |

Simi-organic Cr-containing coating |

0.5 - 3μm |

General Coating |

In non-oxidation environment the coating is normal through 750°C stress relieving annealing. |

good |

very good |

high |

very good |

|

M5 |

Thick environmental friendly coating |

2 - 5μm |

Suits perfectly for mid-sized and heavy machines |

The coating can be resistant to continuous exposure to temperatures of up to 270°C, and well suits for aluminium coating, welding and annealing. |

very good |

good |

high |

good |

|

M6 |

C6 environmental friendly coating |

2 - 8μm |

Suits perfectly for mid-sized and heavy machines, particularly for big generator. |

The coating can be resistant to continuous exposure to temperatures of up to 180°C, and withstands aluminium coating and the burn off process during a machine repair. |

very good |

good |

high |

good |

Note: If users have no special requirements, M4 is the default coating.

Applications

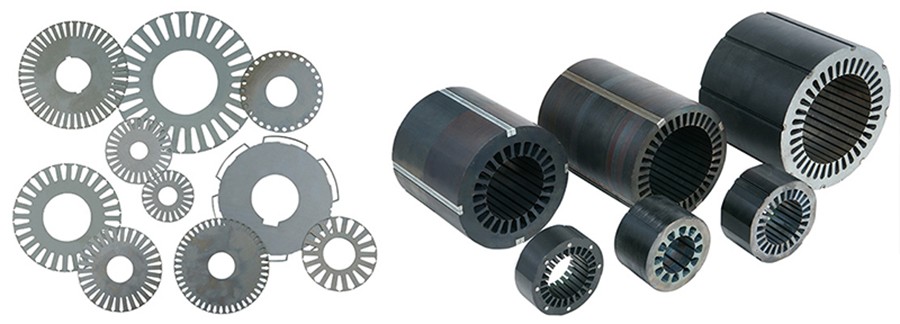

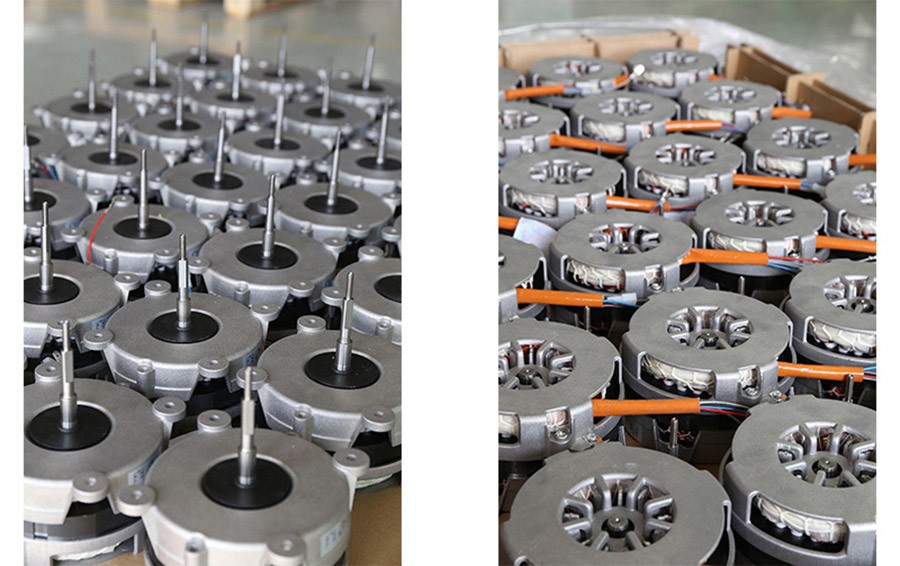

Non-grain oriented silicon has a variety of usage in generators, distributors, and consumption of electricity, etc. Shunge could provide outstanding quality semi-products such as high lamination steel fittings and silicon steel transformer cores.

Packing

We will contact you as soon as possible

Hi! Click one of our members below to chat on