Stainless steel is a type of steel that offers corrosion resistance, high ductility, an attractive appearance, and low maintenance requirements. Our stainless steel products are available in various surface finishes, such as a hairline surface or a mirror surface, catering to different decorative applications. This ensures that our stainless steel products meet diverse aesthetic requirements.

MOQ :

10TPayment :

T/T, L/C at sightProduct Origin :

ChinaShipping Port :

Shenzhen/GuangzhouStainless steel is an iron-based alloy that offers exceptional resistance to rusting and corrosion. It is composed of a minimum of 11% chromium, along with other elements like carbon, nonmetals, and metals, which are added to achieve specific desired properties. The corrosion resistance of stainless steel is primarily due to the formation of a passive film of chromium oxide, which acts as a protective layer. This film enables the material to self-heal and provides ongoing protection in the presence of oxygen.

PRODUCT CHARACTERISTICS & APPLICATIONS

|

Series |

Grade |

Characteristics |

Applications |

|

|

Austenite |

Basic |

SUS304 |

Widely used, corrosion resistant, heat resistant, good mechanical properties in low temperature, no heat treatment hardening, weak magnetism. |

Home kitchen utensils, chemical industry, medical apparatus, building material and decoration |

|

SUS304L |

Better intergranular corrosion resistance, can be heat treated after welding. |

Petroleum equipment, chemical equipment, building material, heat resistant parts and the parts are difficult to heat treat |

||

|

High Tensile Strength |

SUS301 |

Lower content of Cr and Ni than 304 grade. It’s strength, hardness and magnetism can be increased by cold working. |

Trains, air crafts, vehicles, springs |

|

|

SUS301L* |

Improving intergranular corrosion resistance by decreasing content and increasing N content from 301 grade. |

Frame and crust parts of train |

||

|

Deep Drawing |

SUS304Cu |

Better formability than 304 grade by addition of Cu, suitable for deep drawing. |

Domestic appliances |

|

|

SUS304Ni8.5 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

SUS304Ni9 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

High Corrosion Resistance |

SUS316* |

Better corrosion resistance than 304 grade in sea water and other corrosive solutions, higher heat-resistance, good cold work hardening performance, no magnetism . |

Chemical industry, food processing equipments, coastal installations. |

|

|

SUS316L |

Compared with SUS316, this grade has better intergranular corrosion resistance and lower heat-resistance, no magnetism |

Chemical industry and food processing equipments used in severe corrosive condition, coastal installations used |

||

|

SUS321 |

Intergranular corrosion resistant, heat resistant, good formability and weldability, anti-oxidizing in high temperature. |

Jet engine parts, heat exchanger, boiler cover, chemical devices |

||

|

Ferrite |

Basic |

SUS430 |

Typical ferritic stainless steel grade, low thermal expansibility, good formability and antioxygenic property. |

Heat-resistant utensils, combustion devices, domestic appliance, kitchen utensils category, building decorating material |

|

Weldable and Corrosion Resistant

|

SUH409L |

Good formability and weldability, antioxygenic property in high temperature. |

Exhaust system of automobiles |

|

|

SUS436L* |

Good corrosion resistance, formability and weldability. Corrosion resistant to condensates in exhaust piping of automobiles. |

Automobile exhaust piping, boiler |

||

|

SUS444* |

Good corrosion resistance, formability and weldability. Compared with 316L, this grade has better stress corrosion resistance and spot corrosion resistance. |

Water heater, water tank, automobile exhaust piping |

||

|

Martenslte |

Basic |

SUS420J2* |

High post-quenching strength, suitable for wearable parts. |

Knife, pipe nozzles, valves, metal rules and cooking utensils. |

Notes: * refers to none-conventional products, please contact us for details if you have further needs.

PRODUCE SPECIFICATION(For reference)

Table 1: Available Width (Unit: mm)

|

No. |

Width Thickness |

650≤w<850 |

850≤w<950 |

950≤w<1050 |

1050≤w<1150 |

1150≤w<1250 |

1250≤w<1320 |

|

1 |

0.2≤t<0.3 |

|

|

|

|

|

|

|

2 |

0.3≤t<0.4 |

|

|

|

|

|

|

|

3 |

0.4≤t<0.5 |

|

|

|

|

|

|

|

4 |

0.5≤t<0.7 |

|

|

|

|

|

|

|

5 |

0.7≤t<0.9 |

|

|

|

|

|

|

|

6 |

0.9≤t<1.1 |

|

|

|

|

|

|

|

7 |

1.1≤t<1.3 |

|

|

|

|

|

|

|

8 |

1.3≤t<1.7 |

|

|

|

|

|

|

|

9 |

1.7≤t<2.0 |

|

|

|

|

|

|

|

10 |

2.0≤t≤3.0 |

|

|

|

|

|

|

|

11 |

3.0<t≤4.0 |

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

Table 2: Available Surface (Unit: mm)

|

No. |

Width Thickness |

300 Series |

400 Series |

||||||||||||||

|

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

||

|

1 |

0.20≤t<0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

0.25≤t<0.30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

0.30≤t<0.35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

0.35≤t<1.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

1.20≤t<1.50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1.50≤t<2.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

2.00≤t<3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

t=3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

3.00<t≤4.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

4.00<t≤6.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

STEEL GRADE, CHEMICAL COMPOSITION & MECHANICAL PROPERTY

The product are in accordance to the latest revision of Chinese national standard (GB/T3280), Japanese industrial standard (JIS G4305), American of testing materials (AS TM A240) and European norm(EN 10088-2), at customer’s option.

Table 1(a): Steel Grade and Chemical Composition(For reference)

|

Series |

Standard and Steel Designation |

Main Chemical Composition |

|||||||||||

|

JIS |

GB |

ASTM |

EN |

C Max |

Si Max |

Mn Max |

P Max |

S Max |

Ni |

Cr |

Others |

||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

18.00-20.00 |

- |

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

0.15 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

- |

|

|

301B* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.095-0.135 |

0.50-0.80 |

0.60-0.90 |

0.035 |

0.030 |

6.55-6.85 |

16.25-16.75 |

Mo:0.40; Cu:0.40; N:0.045 |

||

|

301S* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.110-0.145 |

0.30-0.60 |

1.60-1.90 |

0.035 |

0.030 |

6.10-6.40 |

16.30-16.90 |

Mo:0.40; Cu:0.40; N:0.04-0.07 |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

N:0.20 |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.50-10.5 |

18.00-20.00 |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-10.5 |

18.00-20.00 |

- |

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

Cu:0.70-1.30 |

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

12.00-15.00 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

316L(ASTM) |

- |

S31603 |

|

0.030 |

0.75 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

17.00-19.00 |

Ti:5*C% |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

- |

16.00-18.00 |

- |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

10.50-11.75 |

Ti:6*C%-0.75 |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

11.00-13.50 |

- |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

16.00-19.00 |

Mo:0.75-1.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

0.50 |

17.00-19.00 |

Ti:[0.20+4*(C+N)]~1.10 Al:0.15; N:0.030 |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

17.00-20.00 |

Mo:1.75-2.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

0.26-0.40 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

12.00-14.00 |

- |

Table 1(b): Steel Grade and Mechanical Property (For reference)

|

Series |

Standard and Steel Designation |

Main Mechanical Property (Solution Treatment or Annealing) |

||||||||||

|

JIS |

GB |

ASTM |

EN |

Yield Strength N/mm² |

Tensile Strength N/mm² |

Elongation % |

Hardness |

Bending |

||||

|

HV |

HRB |

Bending Angle |

Bending Radius |

|||||||||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

|

|

301B* |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

301S* |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

≥215 |

≥550 |

≥45 |

≤218 |

≤95 |

- |

- |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

316L(ASTM) |

- |

S31603 |

|

≥170 |

≥485 |

≥40 |

≤200 |

≤95 |

- |

- |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

≥205 |

≥420 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

≥175 |

≥360 |

≥25 |

≤175 |

≤80 |

180° |

0.5 Time of Thickness |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

≥195 |

≥360 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

≥205 |

≥415 |

≥22 |

≤200 |

≤89 |

180° |

1.0 Time of Thickness |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

≥225 |

≥540 |

≥18 |

≤247 |

≤99 |

- |

- |

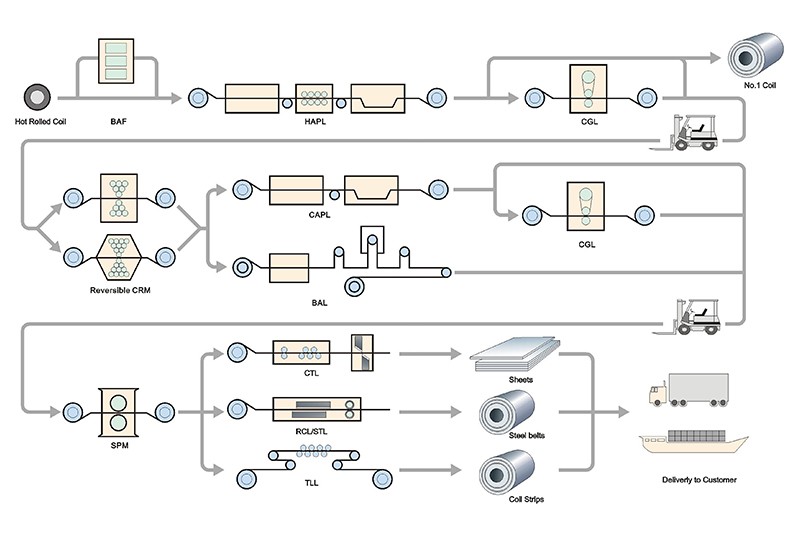

Production Process

|

Application

|

|

|

|

Packing

|

We will contact you as soon as possible

Hi! Click one of our members below to chat on