Stainless steel with its amazing performance of corrosion resistance and uniform surface is an excellent material widely used for nowadays manufacturing, construction. With explicit equipment and skillful stuff, we could process our hot rolled stainless steel with customized service based on your requirement.

MOQ :

10TPayment :

T/T LC at sightProduct Origin :

ChinaShipping Port :

Guangzhou/ ShenzhenStainless steel is generally used in all industries and fields with abundant outstanding advantages. Working with China's leading stainless steel manufacturers and suppliers, Shunge is capable of providing stainless steel in full series such as 200/ 300/ 400... and in all types of forms such as stainless steel tube, coil, plate, sheet, strip with customized service.

Feature

Stainless steel has a great variety of surface finishes, from matt to bright and including brushed and engraved. It can be embossed or tinted, making stainless a unique and aesthetic material. It is often used by architects for building envelopes, interior design and street furniture.

Stainless steel has strong mechanical properties at ambient temperature, especially its combination of ductility, elasticity and hardness allows it to be used in difficult metal forming modes (deep drawing, flat bending, extrusion, etc.), while providing heavy resistance Wear (friction, wear, impact, elasticity, etc.). In addition, it has good mechanical properties at both low and high temperatures.

Stainless steel has the best fire resistance of all metallic materials when used in structural applications, having a critical temperature above 800°C. Stainless steel is ranked A2s1d0 for fire resistance with no toxic fume emissivity.

With a minimum chromium content of 10.5%, stainless steel is continuously protected by a passive layer of chromium oxide that forms naturally on the surface through the reaction of the chromium with oxygen from air or water. If the surface is scratched, it regenerates itself. This particularity give stainless steels their corrosion resistance.

Stainless steel items are easy to clean, usual cleaning products (detergents, soap powders) are sufficient and do not damage the surface. Stainless steel fully meets the requirements of decoration and cooking utensils that require frequent and effective washing.

Stainless steel is the "green material" and is infinitely recyclable. Within the construction sector, its actual recovery rate is close to 100%. It is environmentally neutral and inert when in contact with elements such as water and it does not leach compounds that might modify their composition. These qualities make stainless steel ideally suited to building applications exposed to adverse weather, such as roofs, facades, rainwater recovery systems and domestic water pipes. Stainless steel's longevity fulfils the requirements of sustainable construction, and effective erection, installation and low maintenance guarantee the user an unrivalled service life.

STEEL GRADE, CHEMICAL COMPOSITION & MECHANICAL PROPERTY (For reference)

The product are in accordance to the latest revision of Chinese national standard (GB/T3280), Japanese industrial standard (JIS G4305), American of testing materials (AS TM A240) and European norm(EN 10088-2), for customer’s options.

Table 1(a): Steel Grade and Chemical Composition(For reference)

|

Series |

Standard and Steel Designation |

Main Chemical Composition |

|||||||||||

|

JIS |

GB |

ASTM |

EN |

C Max |

Si Max |

Mn Max |

P Max |

S Max |

Ni |

Cr |

Others |

||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

18.00-20.00 |

- |

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

0.15 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

- |

|

|

301B* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.095-0.135 |

0.50-0.80 |

0.60-0.90 |

0.035 |

0.030 |

6.55-6.85 |

16.25-16.75 |

Mo:0.40; Cu:0.40; N:0.045 |

||

|

301S* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.110-0.145 |

0.30-0.60 |

1.60-1.90 |

0.035 |

0.030 |

6.10-6.40 |

16.30-16.90 |

Mo:0.40; Cu:0.40; N:0.04-0.07 |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

N:0.20 |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.50-10.5 |

18.00-20.00 |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-10.5 |

18.00-20.00 |

- |

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

Cu:0.70-1.30 |

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

12.00-15.00 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

316L(ASTM) |

- |

S31603 |

|

0.030 |

0.75 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

17.00-19.00 |

Ti:5*C% |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

- |

16.00-18.00 |

- |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

10.50-11.75 |

Ti:6*C%-0.75 |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

11.00-13.50 |

- |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

16.00-19.00 |

Mo:0.75-1.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

0.50 |

17.00-19.00 |

Ti:[0.20+4*(C+N)]~1.10 Al:0.15; N:0.030 |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

17.00-20.00 |

Mo:1.75-2.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

0.26-0.40 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

12.00-14.00 |

- |

Table 1(b): Steel Grade and Mechanical Property (For reference)

|

Series |

Standard and Steel Designation |

Main Mechanical Property (Solution Treatment or Annealing) |

||||||||||

|

JIS |

GB |

ASTM |

EN |

Yield Strength N/mm² |

Tensile Strength N/mm² |

Elongation % |

Hardness |

Bending |

||||

|

HV |

HRB |

Bending Angle |

Bending Radius |

|||||||||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

|

|

301B*(宝新) |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

301S*(宝新) |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

≥215 |

≥550 |

≥45 |

≤218 |

≤95 |

- |

- |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

316L(ASTM) |

- |

S31603 |

|

≥170 |

≥485 |

≥40 |

≤200 |

≤95 |

- |

- |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

≥205 |

≥420 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

≥175 |

≥360 |

≥25 |

≤175 |

≤80 |

180° |

0.5 Time of Thickness |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

≥195 |

≥360 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

≥205 |

≥415 |

≥22 |

≤200 |

≤89 |

180° |

1.0 Time of Thickness |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

≥225 |

≥540 |

≥18 |

≤247 |

≤99 |

- |

- |

Table 2: Mechanical property of Hardening Condition

|

Grade |

Hardening Code |

Mechanical Property (Hardening) |

||||

|

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Bending |

||

|

N/mm² |

N/mm² |

% |

HV |

|

||

|

SUS301* (JIS G 4313) |

1/2H |

≥510 |

≥930 |

≥10 |

≥310 |

Less 2.0 Times of Thickness |

|

3/4H |

≥745 |

≥1130 |

≥5 |

≥370 |

Less 2.5 Times of Thickness |

|

|

H |

≥1030 |

≥1320 |

|

≥430 |

- |

|

|

EH |

≥1275 |

≥1570 |

|

≥460 |

- |

|

|

SUS 301* (JIS G 4305) |

1/4H |

≥345 |

≥690 |

≥40 |

|

Less 1.5 Times of Thickness |

|

1/2H |

≥410 |

≥760 |

≥35 |

|

Less 2.0 Times of Thickness |

|

|

3/4H |

≥480 |

≥820 |

≥25 |

|

- |

|

|

H |

≥685 |

≥930 |

≥20 |

|

- |

|

|

SUS 304* (JIS G 4313) |

1/2H |

≥470 |

≥780 |

≥6 |

≥250 |

Less 2.0 Times of Thickness |

|

3/4H |

≥665 |

≥930 |

≥3 |

≥310 |

Less 2.5 Times of Thickness |

|

|

H |

≥880 |

≥1130 |

- |

≥370 |

- |

|

Notes: For the last 2 tables, * refers to none-conventional products, please contact us for details if customers need it.

PRODUCT CHARACTERISTICS & APPLICATIONS

|

Series |

Grade |

Characteristics |

Applications |

|

|

Austenite |

Basic |

SUS304 |

Widely used, corrosion resistant, heat resistant, good mechanical properties in low temperature, no heat treatment hardening, weak magnetism. |

Home kitchen utensils, chemical industry, medical apparatus, building material and decoration |

|

SUS304L |

Better intergranular corrosion resistance, can be heat treated after welding. |

Petroleum equipment, chemical equipment, building material, heat resistant parts and the parts are difficult to heat treat |

||

|

High Tensile Strength |

SUS301 |

Lower content of Cr and Ni than 304 grade. It’s strength, hardness and magnetism can be increased by cold working. |

Trains, air crafts, vehicles, springs |

|

|

SUS301L* |

Improving intergranular corrosion resistance by decreasing content and increasing N content from 301 grade. |

Frame and crust parts of train |

||

|

Deep Drawing |

SUS304Cu |

Better formability than 304 grade by addition of Cu, suitable for deep drawing. |

Domestic appliances |

|

|

SUS304Ni8.5 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

SUS304Ni9 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

High Corrosion Resistance |

SUS316* |

Better corrosion resistance than 304 grade in sea water and other corrosive solutions, higher heat-resistance, good cold work hardening performance, no magnetism . |

Chemical industry, food processing equipments, coastal installations |

|

|

SUS316L |

Compared with SUS316, this grade has better intergranular corrosion resistance and lower heat-resistance, no magnetism |

Chemical industry and food processing equipments used in severe corrosive condition, coastal installations used |

||

|

SUS321 |

Intergranular corrosion resistant, heat resistant, good formability and weldability, anti-oxidizing in high temperature. |

Jet engine parts, heat exchanger, boiler cover, chemical devices |

||

|

Ferrite |

Basic |

SUS430 |

Typical ferritic stainless steel grade, low thermal expansibility, good formability and antioxygenic property. |

Heat-resistant utensils, combustion devices, domestic appliance, kitchen utensils category, building decorating material |

|

Weldable and Corrosion Resistant

|

SUH409L |

Good formability and weldability, antioxygenic property in high temperature. |

Exhaust system of automobiles |

|

|

SUS436L* |

Good corrosion resistance, formability and weldability. Corrosion resistant to condensates in exhaust piping of automobiles. |

Automobile exhaust piping, boiler |

||

|

SUS444* |

Good corrosion resistance, formability and weldability. Compared with 316L, this grade has better stress corrosion resistance and spot corrosion resistance. |

Water heater, water tank, automobile exhaust piping |

||

|

Martenslte |

Basic |

SUS420J2* |

High post-quenching strength, suitable for wearable parts. |

Knife, pipe nozzles, valves, metal rules and cooking utensils. |

Notes: * refers to none-conventional products, please contact us for details if you have further needs.

PRODUCE SPECIFICATION (For reference)

Table 1: Available Width (Unit: mm)

|

No. |

Width Thickness |

650≤w<850 |

850≤w<950 |

950≤w<1050 |

1050≤w<1150 |

1150≤w<1250 |

1250≤w<1320 |

|

1 |

0.2≤t<0.3 |

|

|

|

|

|

|

|

2 |

0.3≤t<0.4 |

|

|

|

|

|

|

|

3 |

0.4≤t<0.5 |

|

|

|

|

|

|

|

4 |

0.5≤t<0.7 |

|

|

|

|

|

|

|

5 |

0.7≤t<0.9 |

|

|

|

|

|

|

|

6 |

0.9≤t<1.1 |

|

|

|

|

|

|

|

7 |

1.1≤t<1.3 |

|

|

|

|

|

|

|

8 |

1.3≤t<1.7 |

|

|

|

|

|

|

|

9 |

1.7≤t<2.0 |

|

|

|

|

|

|

|

10 |

2.0≤t≤3.0 |

|

|

|

|

|

|

|

11 |

3.0<t≤4.0 |

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

Table 2: Available Surface (Unit: mm)

|

No. |

Width Thickness |

300 Series |

400 Series |

||||||||||||||

|

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

||

|

1 |

0.20≤t<0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

0.25≤t<0.30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

0.30≤t<0.35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

0.35≤t<1.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

1.20≤t<1.50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1.50≤t<2.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

2.00≤t<3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

t=3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

3.00<t≤4.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

4.00<t≤6.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

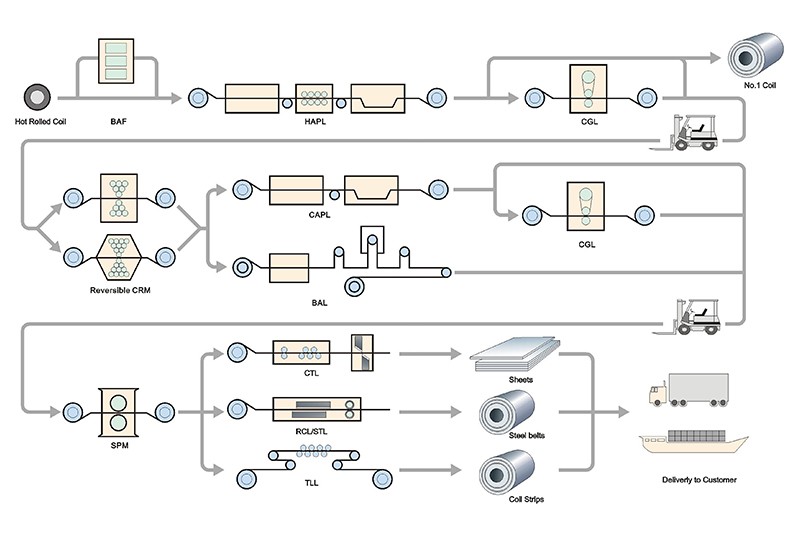

Manufacturing process

|

Application

|

|

|

|

Packing

|

We will contact you as soon as possible

Hi! Click one of our members below to chat on