Electro-galvanized steel has good corrosion resistance, especially as the surface of the coating is evenly bonded, corrosive gases or liquids are not easy to permeate the interior. Zinc coating is more even and uniform, suitable for more demanding home appliance and automobile industry.

MOQ :

10TPayment :

T/T LC at sightProduct Origin :

ChinaShipping Port :

Guangzhou/ ShenzhenCharacteristics of Electro-Galvanized Steel

Corrosion Resistance

The zinc is solidfied to produce the outer layer of the pure zinc coating, a thin film is formed on the surface to prevent it from being corroded during exposure to acid and alkaline environments, which protected the steel body for a long time.

Paintability

Electro-galvanized steel has various colors be coated after the chemical process, which can be customized to customer requirements. Electro-galvanized steel is beautiful and decorative. Its flat and uniform surface provides good conditions for painting and improves its paint adhesion and anticorrosion properties after painting.

Weldability

Electro-galvanized steel has good ductility and surface not is not easily fall off during various processing, bending and handling.

Formability

Compared with hot-dip galvanized steel sheet, electro-galvanized sheet has less galvanized surface. And in the process of processing, it is not affected by heat treatment, so is has the same material and processing performance as the original plate (cold plate)

Conductivity

Anti-fingerprint resin treatment (without phosphate surface treatment,insulator) ensure the excellent electric conductivity, which has low resistance of below 0.1ms.

Products Classification

|

Product |

Coating Structure |

Characteristics |

Application |

|

anti-finger paint |

Steel+ Zn+ AFP(1~1.5um) |

Conductivity Appearance Durability Anti-Corrosion Anti-finger |

For conductivity needs For home appliance |

|

M+motor |

Steel+ Zn+ AFP(1~1.5um) |

Abrasion resistance Wearing strength |

Motor case material |

|

Non-treatment+oil |

Steel+Zn+oil |

Weld-ability Conductivity |

PCM for substance weld-ability needs Construction needs PCM |

|

Available size |

Thickness:0.4~2.0mm Width:800~1380mm Coating weight:8~51 g/㎡(single side) Max coil weight:≤25MT standard:ASTM, DIN,ISI, GB,BS,JIS |

||

|

Surface Treatment: Oiling, chemical passivation, phosphating, fingerprint resistant, self-lubricating fingerprint resistant. |

|||

|

Remarks:The table above show the widest range of product dimensions. For a detail acceptable order range, please contact Sales and Marketing Division. |

|||

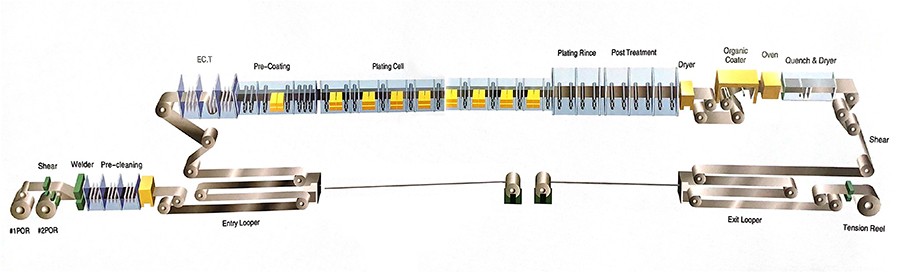

EGI Production Line

Mechanical Properties (For reference)

|

Item |

Mechanical Properties(%) |

Application |

|||

|

YP(N/mm²) |

TS(N/mm²) |

EL(%) |

|||

|

Cold Rolled Coil |

SECC (JISG3313) |

180-230 |

≥270 |

≥37 |

Commercial Usage |

|

SECD (JISG3313) |

130-180 |

≥270 |

≥39 |

Drawing usage |

|

Application

|

|

Packing

We will contact you as soon as possible

Hi! Click one of our members below to chat on