Electro-galvanized steel finds extensive application in commercial electric appliances and various manufacturing industries. Shunge Steel is a reliable provider of high-quality electro-galvanized coils, sheets, strips, and plates that comply with the JISG3313 standard. You can trust Shunge Steel for your electro-galvanized steel needs.

MOQ :

10TPayment :

T/T LC at sightProduct Origin :

ChinaShipping Port :

Guangzhou/ ShenzhenElectro-galvanized steel features a surface that is electroplated with zinc, resulting in a flat and smooth texture. This meticulous surface finish provides a pleasing tactile experience. As a result, electro-galvanized steel is commonly utilized for the surface treatment of key components in home appliances, automobiles and their accessories, as well as in various other industries and fields.

Characteristics of Electro-Galvanized Steel

Corrosion Resistance

The zinc electroplating on the surface of the steel provides excellent corrosion resistance, protecting the underlying material from rust and oxidation.

Smooth and Uniform Coating

The electroplating process ensures a flat and uniform zinc coating, resulting in a smooth surface finish that is aesthetically appealing.

Enhanced Durability

Electro-galvanized steel exhibits increased durability and longevity due to its protective zinc layer, making it suitable for various applications that require long-lasting performance.

Formability

This type of steel is highly formable, allowing it to be easily shaped and molded into different configurations, making it versatile for use in a wide range of manufacturing processes.

Good Weldability

Electro-galvanized steel offers good weldability, enabling efficient joining with other metal components without compromising the integrity of the material.

Cost-Effective Solution

Electro-galvanized steel is a cost-effective solution compared to other corrosion-resistant materials, making it a preferred choice in industries where budget considerations are important.

Paintability

Electro-galvanized steel has various colors be coated after the chemical process, which can be customized to customer requirements. Electro-galvanized steel is beautiful and decorative. Its flat and uniform surface provides good conditions for painting and improves its paint adhesion and anticorrosion properties after painting.

Products Classification

|

Product |

Coating Structure |

Characteristics |

Application |

|

anti-finger paint |

Steel+ Zn+ AFP(1~1.5um) |

Conductivity Appearance Durability Anti-Corrosion Anti-finger |

For conductivity needs For home appliance |

|

M+motor |

Steel+ Zn+ AFP(1~1.5um) |

Abrasion resistance Wearing strength |

Motor case material |

|

Non-treatment+oil |

Steel+Zn+oil |

Weld-ability Conductivity |

PCM for substance weld-ability needs Construction needs PCM |

|

Available size |

Thickness:0.4~2.0mm Width:800~1380mm Coating weight:8~51 g/㎡(single side) Max coil weight:≤25MT standard:ASTM, DIN,ISI, GB,BS,JIS |

||

|

Surface Treatment: Oiling, chemical passivation, phosphating, fingerprint resistant, self-lubricating fingerprint resistant. |

|||

|

Remarks:The table above show the widest range of product dimensions. For a detail acceptable order range, please contact Sales and Marketing Division. |

|||

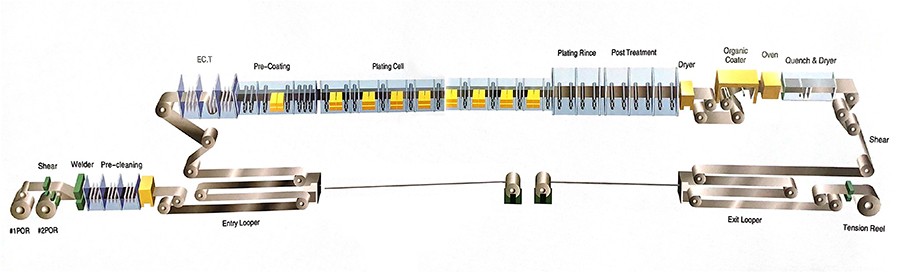

EGI Production Line

Mechanical Properties (For reference)

|

Item |

Mechanical Properties(%) |

Application |

|||

|

YP(N/mm²) |

TS(N/mm²) |

EL(%) |

|||

|

Cold Rolled Coil |

SECC (JISG3313) |

180-230 |

≥270 |

≥37 |

Commercial Usage |

|

SECD (JISG3313) |

130-180 |

≥270 |

≥39 |

Drawing usage |

|

Application

Electro-galvanizing steel with great performance in anti-corrosion, which is why it's generally seen in home appliance industry.

|

|

Packing

|

We will contact you as soon as possible

Hi! Click one of our members below to chat on