There're countless types of pumps and the usages are different accordingly. One thing for sure is that you would definitely love to choose the very type that fits all your need. Shunge has abundant pump products that might interest you.

Product Origin :

ChinaShipping Port :

Shenzhen/GuangzhouPayment :

T/T, L/C at sightHorizontal multistage centrifugal pump -- SGE/ SGF series

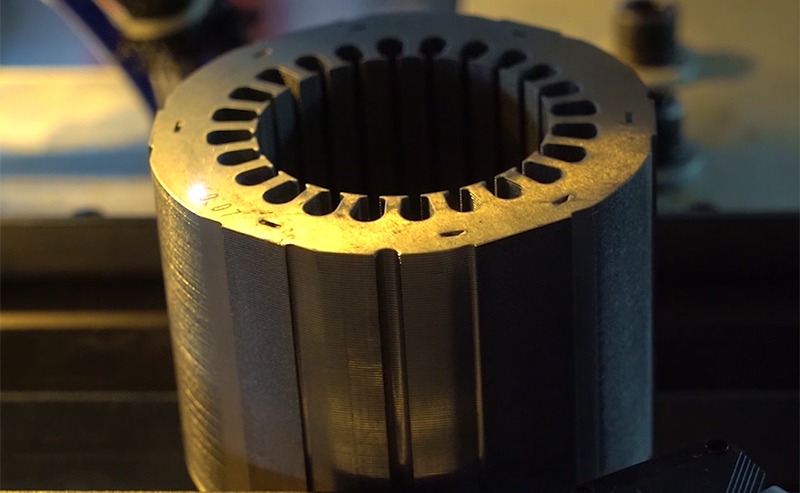

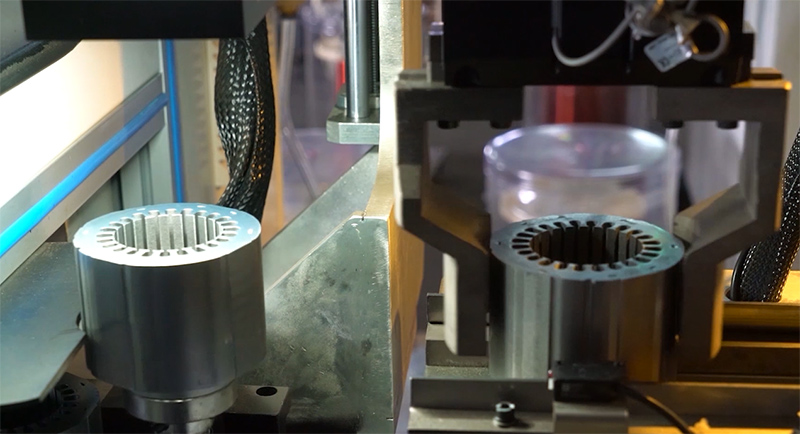

We manufacture most of the state-of-the-art stainless steel pumps that are popular in nowadays market and have patent rights for some designs. Since we are the A-level silicon steel distribitor of SHOUSTEEL which got the most advance production line in China and it is the best choice of making the most essential parts of pumps---the motors. From the smallest parts of the core to other parts, all the way down to the final product, we control every step of the production and warmly welcome OEM orders.

Stainless steel parts production line

Decoiling line for steel coil

|

|

high lamination semi-finished product stator

professional automatic stator winding line

Seamless pipe cutting line

Assembling workshop

|

|

|

final finished to product -- all types of stainless steel electric pumps

Other than strictly monitoring the production line, we also pay full attention to the quality control and quality test.

Water-injection quality test before packaging

--- SGE SERIES ---

|

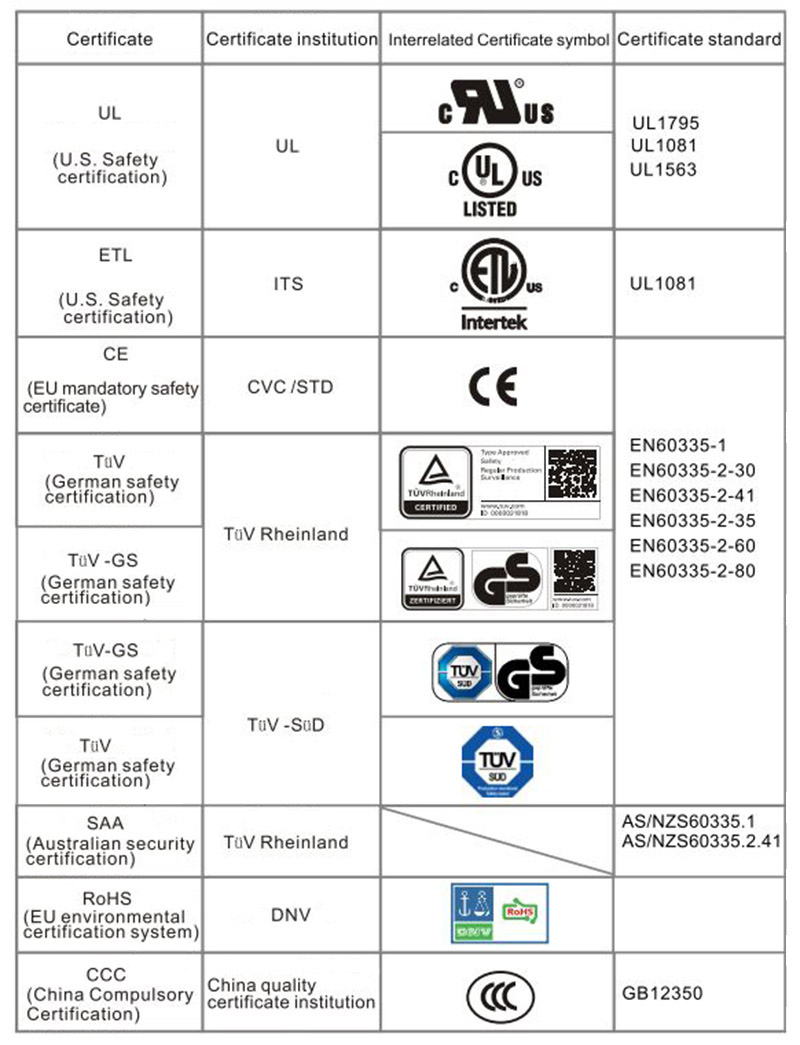

Certifications:

EN60335-1: 2012

EN62233: 2008

EN60335-2-41: 2003+A:2004+A2:2010

EN809: 1998+A1:2009+AC2010

EN55014-1: 2006+A1:2009+A2:2011

EN55014-2: 1997+A1:2007+A2:2008

EN61000-6-1: 2007

EN61000-6-3: 2007+A1:2011

EN61000-3-2: 2006+A1:2009+A2:2009

EN61000-3-3: 2008

Working conditions

Medium temperature:

Low temperature: -20~+70℃

Standard model: +15~+70℃

High temperature: +70~+104℃

Environmental temperature: <=50℃

Max. Working pressure: 1.0MPa

Technical parameter list FOR SGE SERIES

|

Model |

Power(P2) kW |

(Amps) |

Rated head (m) |

Rated flow (m3/h) |

Curve |

DNA |

DNM |

G.W. (kg) |

Packing size |

|

|

220V/50Hz |

380V/50Hz |

|||||||||

|

SGE1-20(T) |

0.25 |

2.0 |

0.7 |

13.5 |

1 |

1 |

G1 |

G1 |

7.6 |

370x195x255 |

|

SGE1-30(T) |

0.25 |

2.0 |

0.7 |

21 |

1 |

2 |

G1 |

G1 |

7.8 |

370x195x255 |

|

SGE1-40(T) |

0.25 |

2.0 |

0.7 |

27 |

1 |

3 |

G1 |

G1 |

8.3 |

445x195x255 |

|

SGE1-50(T) |

0.37 |

2.4 |

1.0 |

33 |

1 |

4 |

G1 |

G1 |

8.5 |

445x195x255 |

|

SGE1-60(T) |

0.37 |

2.4 |

1.0 |

37 |

1 |

5 |

G1 |

G1 |

9.1 |

445x195x255 |

|

SGE2-20(T) |

0.25 |

2.0 |

0.7 |

16 |

2 |

6 |

G1 |

G1 |

7.6 |

370x195x255 |

|

SGE2-30(T) |

0.37 |

2.4 |

1.0 |

24 |

2 |

7 |

G1 |

G1 |

7.9 |

370x195x255 |

|

SGE2-40(T) |

0.55 |

3.8 |

1.4 |

32 |

2 |

8 |

G1 |

G1 |

8.6 |

475x195x255 |

|

SGE2-50(T) |

0.55 |

3.8 |

1.4 |

40 |

2 |

9 |

G1 |

G1 |

9.8 |

475x195x255 |

Application:

|

|

--- SGF SERIES ---

|

|

Certifications:

EN60335-1: 2012

EN62233: 2008

EN60335-2-41: 2003+A:2004+A2:2010

EN809: 1998+A1:2009+AC2010

EN55014-1: 2006+A1:2009+A2:2011

EN55014-2: 1997+A1:2007+A2:2008

EN61000-6-1: 2007

EN61000-6-3: 2007+A1:2011

EN61000-3-2: 2006+A1:2009+A2:2009

EN61000-3-3: 2008

Working conditions

Medium temperature:

Low temperature: -20~+70℃

Standard model: +15~+70℃

High temperature: +70~+104℃

Environmental temperature: <=50℃

Max. Working pressure: 1.0MPa

Technical parameter list FOR SGF SERIES --- FOR 50Hz

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF2-20T |

0.37 |

2 |

14 |

|

SGF2-30T |

0.37 |

21 |

|

|

SGF2-40T |

0.55 |

28 |

|

|

SGF2-50T |

0.55 |

35 |

|

|

SGF2-60T |

0.75 |

42 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF4-20T |

0.55 |

4 |

15 |

|

SGF4-30T |

0.75 |

22 |

|

|

SGF4-40T |

0.75 |

30 |

|

|

SGF4-50T |

1.0 |

38 |

|

|

SGF4-60T |

1.0 |

45 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF8-10T |

0.55 |

8 |

12 |

|

SGF8-15T |

0.75 |

20 |

|

|

SGF8-20T |

1.0 |

24 |

|

|

SGF8-25T |

1.5 |

27 |

|

|

SGF8-30T |

1.85 |

36 |

|

|

SGF8-35T |

2.2 |

43 |

|

|

SGF8-40T |

2.2 |

48 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF8-10BT |

0.55 |

8 |

9 |

|

SGF8-20BT |

0.75 |

19 |

|

|

SGF8-30BT |

1.1 |

26 |

|

|

SGF8-40BT |

1.5 |

37 |

|

|

SGF8-50BT |

2.2 |

46.5 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF12-10T |

1.0 |

12 |

13.5 |

|

SGF12-15T |

1.5 |

20 |

|

|

SGF12-20T |

1.85 |

28 |

|

|

SGF12-25T |

2.2 |

33.5 |

|

|

SGF12-30T |

3.0 |

39 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF12-10BT |

0.75 |

12 |

9.5 |

|

SGF12-20BT |

1.1 |

19.5 |

|

|

SGF12-30BT |

1.85 |

29.5 |

|

|

SGF12-40BT |

2.2 |

29.5 |

|

|

SGF12-50BT |

3.0 |

50 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF16-10T |

1.0 |

16 |

10 |

|

SGF16-20T |

1.5 |

20 |

|

|

SGF16-30T |

2.2 |

30 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF20-10T |

1.0 |

20 |

10.5 |

|

SGF20-20T |

1.85 |

20 |

|

|

SGF20-30T |

3.0 |

31.5 |

Technical parameter list FOR SGF SERIES --- For 60Hz

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF2-20T |

0.37 |

2 |

20 |

|

SGF2-30T |

0.55 |

31 |

|

|

SGF2-40T |

0.75 |

42 |

|

|

SGF2-50T |

0.75 |

51 |

|

|

SGF2-60T |

1.0 |

63 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF4-20T |

0.75 |

4 |

24 |

|

SGF4-30T |

1.0 |

36 |

|

|

SGF4-40T |

1.1 |

42 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF8-10T |

1.0 |

8 |

18 |

|

SGF8-15T |

1.5 |

28 |

|

|

SGF8-20T |

1.85 |

36 |

|

|

SGF8-25T |

2.2 |

46 |

|

|

SGF8-30T |

3.0 |

58 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF8-10BT |

0.75 |

8 |

12 |

|

SGF8-20BT |

1.5 |

25 |

|

|

SGF8-30BT |

2.2 |

39 |

|

|

SGF8-40BT |

3.0 |

52 |

|

|

SGF8-50BT |

3.0 |

65 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF12-10T |

1.5 |

12 |

18 |

|

SGF12-15T |

2.2 |

34 |

|

|

SGF12-20T |

3.0 |

36 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF12-10BT |

1.1 |

12 |

15 |

|

SGF12-20BT |

2.2 |

31 |

|

|

SGF12-30BT |

3.0 |

48 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF16-10T |

1.5 |

16 |

14 |

|

SGF16-20T |

3.0 |

28 |

|

|

SGF16-30T |

4.0 |

42 |

|

Model |

Power(P2) kW |

Rated flow (m3/h) |

Rated head (m) |

|

SGF20-10T |

1.85 |

20 |

16 |

|

SGF20-20T |

4.0 |

32 |

Selection of pumps:

1. Ensure the rated flow(Q) and rated head(H), see list of technical parameters of rated work point parameters, determine the pump type and

power of motor. (Single-phase: 220-240V, Three- phase: 380-415V)

2. Ensure the Voltage(V), Frequency(Hz) and Phase(PH) of the motor, specially pay attention to the frequency of the user area.

3. Refer to the liquid temperature, ensure the different material of the pump (SUS304, SUS316) and different mechanical seal.

4. Refer to the option manual of CMF, CM, CMH for the information of dimension, performance and the structure.

Application:

|

|

Shunge has a huge range of stainless steel products for your options. Detail information including specification or usage will be appreciated which will speed up the quotation process.

We will contact you as soon as possible

Hi! Click one of our members below to chat on