Silicon steel is a widely used magnetic material in the transformer manufacturing industry, including both C.R.N.G.O silicon steel and C.R.G.O silicon steel, especially in the production of small transformers and household appliances.

As for customers, knowing the main factors that effect the electromagnetic properties of silicon steel sheet could make it easier to suit requirements with corresponding silicon steel products.

Part 1 - Effect of alloying elements on electromagnetic properties

The chemical compositions in silicon steel, especially the contents of alloying elements such as Si and C, have been proved important to improve the electromagnetic properties of silicon steel sheet.

--- Silicon content

Silicon has an influence on the electromagnetic properties, which increases the resistance and reduces the eddy current loss. Silicon could also promote ferrite grain coarsening, reduce coercivity, reduce the anisotropy of the crystal, thus magnetization increases and hysteresis loss decreases. The silicon steel sheet has strong magnetic inductance under weak magnetic field. Instead, under strong magnetic field, silicon decreases the magnetic inductivity of steel because saturation magnetic inductivity decreases by 500 Gauss for every 1% silicon increased.

--- Carbon content

Carbon is harmful to the magnetic properties of silicon steel sheet. It increases coercivity and hysteresis loss, and reduces magnetic sensation intensity. If the carbon content exceeds 0.0296% in the finished silicon steel sheet, the orientation of the silicon steel will be partially or completely destroyed during high temperature annealing.

Therefore, for GOES (grain oriented electrical steel), there won’t be high carbon content; while NGOES (non grain oriented electrical steel), whose carbon content is more than 0.02%, could not be used to produce high steel grade products. The iron loss increases with the adding of carbon content in the silicon steel sheet.

Part 2 - Effect of microstructures on electromagnetic properties

--- Grain size

The grain size of the silicon steel sheet depends on grains after annealing, which is normally the amount of grains per unit area. During actual productions, if the grains are too large, not all the carbon could precipitate as carbides along the grain boundaries the way it’s supposed to, some carbon atoms are dissolved in the ferrite as interstitial solid solutions. Therefore, as the grain size increases, the iron loss increases instead.

--- Thickness of the sheet

The thinner the silicon steel sheet, the smaller the eddy current loss, and thus the smaller the total core loss of the silicon steel sheet. Therefore, silicon steel plates are often made into thin sheets as required. As the thickness of the steel plate decreases from 0.5mm to 0.2mm, the B25 value decreases gradually; as the thickness continues to decrease to 0.10-0.05mm, the B25 value decreases more sharply. The difference between the B25 value of 0.5mm and 0.05mm thick hot-rolled transformer steel is 500-1100 Gauss.

Part 3 - Effect of processing technics on electromagnetic properties

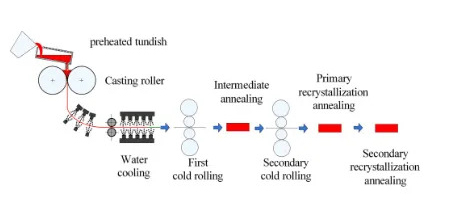

Non-oriented silicon steel cold rolling process

The rolling of silicon steel sheets has a significant impact on the microstructure of steel sheets after annealing, and there’s a huge difference in electromagnetic properties. Ordinary non-oriented silicon steel is generally produced by primary cold rolling, and high-grade non-oriented silicon steel is often produced by secondary cold rolling. After the silicon steel is cold-rolled, ferrite grains would be larger and the grain boundaries would be less, therefore the magnetic resistance would be lower and the hysteresis loss would be smaller.

Conclusion

The rolling process of silicon steel sheet is not only influenced by alloy elements, but also the main factors such as grain size, steel sheet thickness and rolling process. With strict precision control and quality check, sophisticated technology used in manufacturing silicon steel sheet of pime quality is what makes Shunge a reliable and professional silicon steel supplier. Feel free to contact us to gather more further information.

We will contact you as soon as possible

Hi! Click one of our members below to chat on