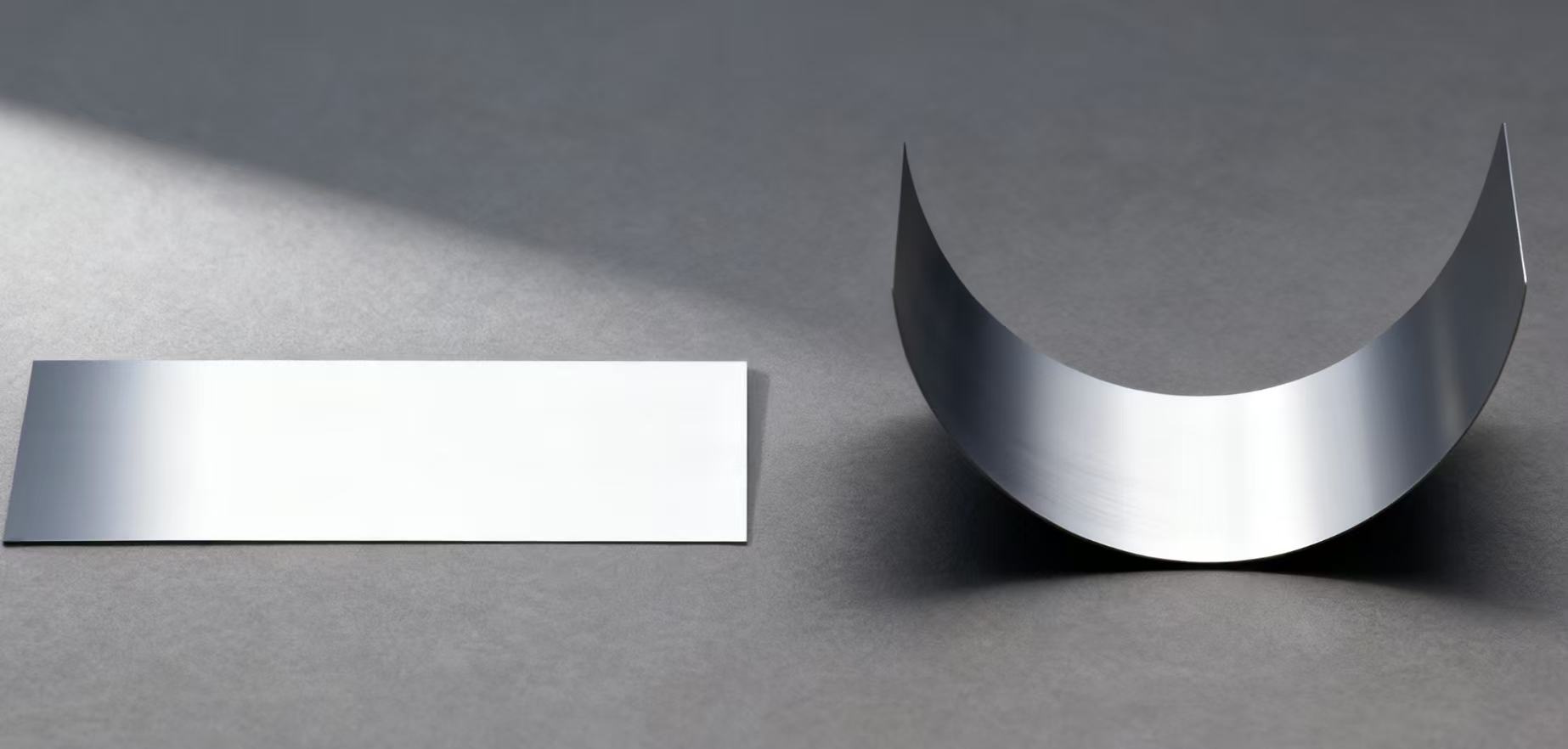

Silicon steel is not soft iron. They are two different soft magnetic materials, with distinct differences in composition, properties, and primary applications. To help you quickly grasp the core differences, the following information summarizes their key characteristics.

1. Silicon steel (silicon steel sheet):

Silicon steel is primarily composed of an iron-silicon alloy, with the silicon content generally ranging from 0.5% to 4.8%. Its key features are high resistivity, high magnetic permeability, low coercive force, and minimal eddy current losses. Nevertheless, as the silicon content rises, the brittleness of silicon steel will increase accordingly. It is predominantly applied in the field of alternating current, such as in the cores of electric motors, transformers, and relays.

2. Soft Iron (Electromagnetic Pure Iron / Industrial Pure Iron):

The primary component of soft iron is high-purity iron, with a carbon content below 0.04% and minimal traces of other impurity elements. Its key characteristics include high saturation magnetization, low cost, and excellent processability. However, due to its low resistivity, it exhibits significant eddy current losses under alternating magnetic fields. Therefore, it is generally applied in direct current (DC) or static magnetic fields, such as in electromagnetic cores, pole shoes, and magnetic shielding covers.

Why the confusion?

Silicon steel and soft iron are often discussed together because they are both soft magnetic materials. These materials share a narrow hysteresis loop, are easily magnetized, and are easily demagnetized. This means they efficiently direct and concentrate magnetic flux lines, and their magnetism quickly disappears after the magnetic field disappears, unlike magnets that retain their magnetism for long periods of time.

Historically, early motors and transformers did use soft iron or low-carbon steel directly as cores. However, it was later discovered that adding silicon to pure iron significantly improved its performance under alternating current (AC). This led to the development of silicon steel specifically for AC applications, which gradually became a mainstream material in the power industry.

Summary:

Simply put, you can understand their roles as follows:

Silicon steel is more like a specialist specialized for AC environments, sacrificing some toughness (the addition of silicon causes brittleness) to achieve high resistivity, effectively reducing eddy current losses.

Soft iron is a powerhouse in DC or static magnetic fields. Its extremely high saturation magnetization generates a strong magnetic field, but it cannot withstand the high-frequency magnetization reversals of AC.

We will contact you as soon as possible

Hi! Click one of our members below to chat on