Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Dec 30, 2025

Ultra-thin silicon steel (especially 0.1-0.2mm thick) is a core material for drive motors in new energy vehicles, and its technical level directly affects the efficiency, power density, and overall vehicle performance of the motor.

1. Improved energy efficiency: Generally speaking, the thinner the silicon steel sheet, the lower the eddy current loss. For example, reducing the thickness of the silicon steel sheet from 0.5mm to 0.1mm can reduce eddy current loss to 1/25 of the original. Therefore, new energy vehicle motors made of ultra-thin silicon steel can reduce energy waste and extend the driving range.

2. Power density: Thinner silicon steel allows motors to operate at higher speeds, thus increasing power density. For example, motors using 0.1mm ultra-thin silicon steel can reach speeds of up to 31,000 rpm. Motors made with ultra-thin silicon steel output more power in the same volume, or reduce motor size for the same power, contributing to vehicle weight reduction.

3. Reduce iron loss: Iron loss is a key indicator for measuring the energy loss of silicon steel sheets. Ultra-thin silicon steel has a lower iron loss value, which can directly reduce the heat generation and energy waste during motor operation, and help improve output power and range.

Ultra-thin silicon steel is a crucial component in the performance race of new energy vehicles.

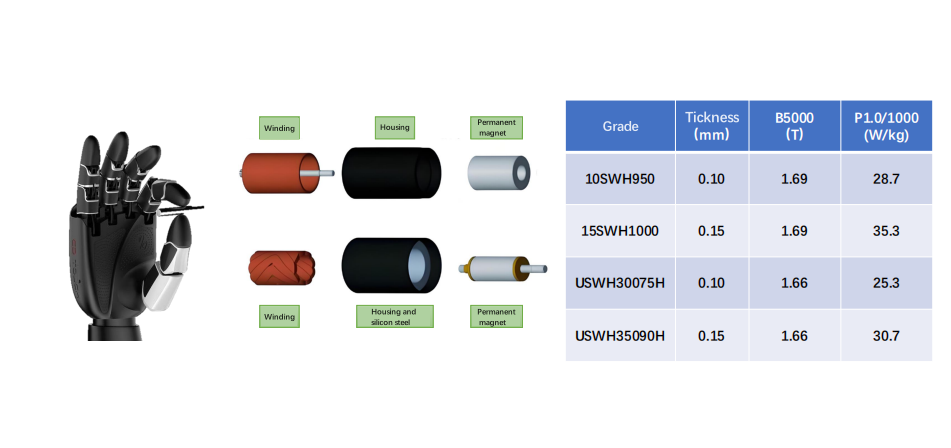

As material thickness continues to decrease to 0.1mm and below, the motors in new energy vehicles will become more powerful, efficient, and compact. The development of ultra-thin silicon steel continues, with a clear trend towards thinner, higher-performance (lower iron loss, higher strength) and broader applications (expanding from new energy vehicles to low-altitude aircraft, humanoid robots, etc.).

Shungesteel now offers ultra-thin silicon steel with a thickness of 0.1-0.2 mm, suitable for use in electric motors for new energy vehicles, providing high-quality material solutions for manufacturers of high-performance electric motors for new energy vehicles.Welcome to learn more.

Read More

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots