What impact does steel lamination punching have on motor performance?

What impact does steel lamination punching have on motor performance?

Feb 02, 2024

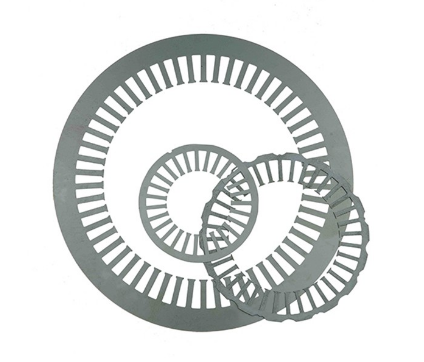

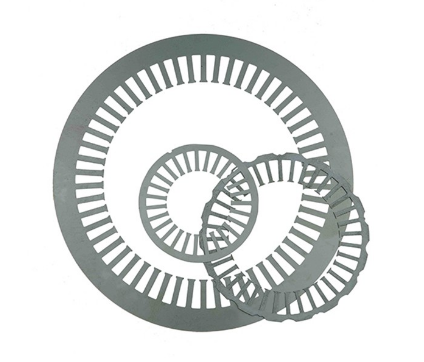

The punch size of the steel lamination is given by the design. The following discusses the factors that affect quality in manufacturing when the design remains unchanged.

1. Loss and magnetic permeability of silicon steel sheets

The specific loss properties of silicon steel sheets from different manufacturers and different batch numbers from the same manufacturer are not exactly the same. So they have a large impact on the motor core lamination or the EI lamination.

Although there are standard prescribed values, they fluctuate within a certain range. If the amplitude of the fluctuation is relatively large, or the material of the silicon steel sheet itself does not meet the requirements, then the use of such silicon steel sheets on the motor will greatly affect the performance of the motor, especially for medium and large motors, where iron loss accounts for 10% of the loss. The larger the proportion, the more obvious the impact on performance (mainly temperature rise and power factor). This is a hidden danger that is difficult to detect from the electromagnetic design.

2. Silicon steel sheet mold is out of tolerance

Silicon steel sheet molds, such as slot punching dies and release molds, have a gap between the punch and the die that gradually increases during use. Some manufacturers are still dealing with production when the mold is out of tolerance, and the consequences are: the punching burrs are significantly increased. If the burr is large, the iron loss and no-load current will increase, causing the temperature rise of the motor to increase, the power factor to decrease, and the efficiency to decrease.

3. Insulation between silicon steel sheets

The insulation between silicon steel sheets can suppress the eddy current in the iron core, thereby reducing the resulting eddy current loss (it is included in the iron loss). The insulating layer between chips is formed in the following three ways:

(1) Inter-chip insulation composed of the paint film of the cold-rolled silicon steel sheets;

(2) The motor manufacturer applies insulating paint on the punched sheets without paint film;

(3) The motor manufacturer oxidizes the punched sheets to form an insulating layer .

Read More

What impact does steel lamination punching have on motor performance?

What impact does steel lamination punching have on motor performance?