Why Pursue "Ultra-thin" Silicon Steel?

Why Pursue "Ultra-thin" Silicon Steel?

Nov 20, 2025

The pursuit of "ultra-thin" silicon steel is driven by the core objective of achieving higher energy efficiency, meeting the demands of high-frequency applications, and promoting the miniaturization and lightweighting of equipment.

The fundamental advantage of the "ultra-thin silicon steel" design lies in the principles of physics. In an alternating magnetic field, eddy currents are generated inside the silicon steel sheet, causing energy to be lost as heat (eddy current loss). Thinner silicon steel sheets confine eddy currents to a narrower vertical cross-section, effectively increasing the resistance of the eddy current path and thus suppressing eddy current loss. Therefore, the higher the operating frequency, the thinner the silicon steel sheet needs to be.

However, the pursuit of "ultra-thin silicon steel" also comes with enormous technological challenges. Reducing thickness means an exponential increase in the demands of process control, especially in rolling and annealing, where even the slightest deviation can lead to strip breakage. Simultaneously, as the silicon content increases (aimed at improving resistivity and optimizing magnetic properties), the material's brittleness increases significantly, making the rolling and processing of ultra-thin products extremely difficult.

The development of "ultra-thin silicon steel" is driven by clear high-end application demands. For example, the new energy vehicle industry pursues high-speed electric drive systems (such as BYD's 30,000 RPM motor). High speed means high frequency, requiring the use of silicon steel sheets as thin as 0.20mm or even thinner to control iron losses, while simultaneously achieving motor miniaturization and weight reduction. In fields such as high-end medical equipment and eVTOL low-altitude aircraft, the extreme requirements for motor size, weight, and response speed are also driving the development of ultra-thin silicon steel technology at 0.15mm, 0.10mm, and even 0.04mm.

Shunge Steel's ultra-thin non-oriented silicon steel, with its superior magnetic properties, has become an ideal material choice for many high-end manufacturing fields. It features low iron loss, high magnetic permeability, and stable magnetic properties, significantly improving energy conversion efficiency. Shunge Steel closely monitors the technological frontiers and development trends of ultra-thin silicon steel, and is committed to providing customers with advanced material solutions.

Read More

Low-iron-loss motor laminated silicon steel helps new energy vehicles achieve a leap in performance.

Low-iron-loss motor laminated silicon steel helps new energy vehicles achieve a leap in performance.

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

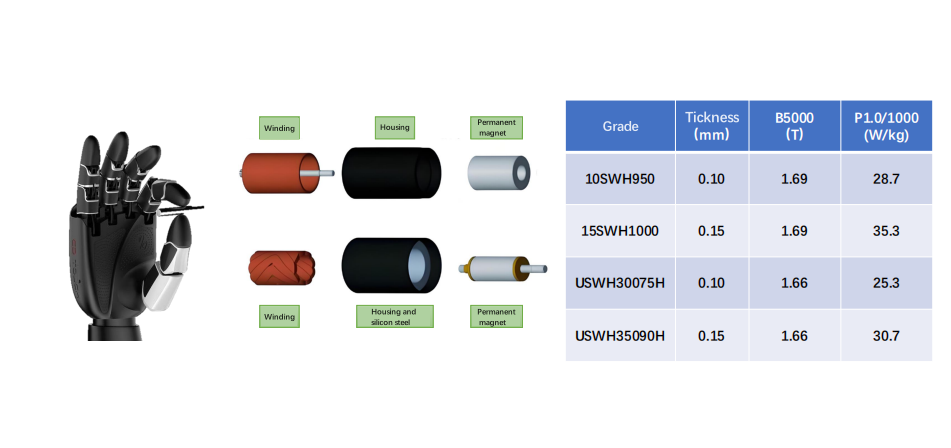

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

What are the advantages of using ultra-thin silicon steel in axial cores

What are the advantages of using ultra-thin silicon steel in axial cores

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

Why Pursue "Ultra-thin" Silicon Steel?

Why Pursue "Ultra-thin" Silicon Steel?