Shunge Silicon Steel Domestic Sales Team

Shunge Silicon Steel Domestic Sales Team

Mar 13, 2023

Our Domestic Sales Department of Silicon Steel has over 10 years' history, which now consists of 6 experienced and professional team members. Product range includes: Cold Rolled Non Grain Oriented Silicon Steel and Cold Rolled Grain Oriented Silicon Steel. Sales volume has reached 1,500 tons every month. Our end customers cover many industries: motors, transformers, manufactures, home appliance factories such as Media, pumps industry which is a listed company, car manufacturers including Japanese and Korean brands.

Silicon Steel Domestic Sales Team and Overseas Sales Team

Among this amazing team, all the members have been working hard for more than 10 years to offer prime products and devoted service to customers, witnessing the growth of Shunge Steel and being more and more professional in silicon steel one-stop supply chain. On the 15th anniversary, they were awarded for the prize of "Outstanding Service".

We work closely with Chinese leading steel mills such as Shou Steel, Bao Steel, An Steel, etc. Especially, we’re the A-level agent of Shou Steel and Bao Steel - which means we have regular stock of 180,000 tons annually for most general steel grades and could ensure high quality, competitive pricing and fast delivery. Moreover, we have close long-term partnerships with private steel mills in China as well.

Raw materials are optional for different pricing so we could be your flexible steel supplier.

Regular warehouse stocking of silicon steel

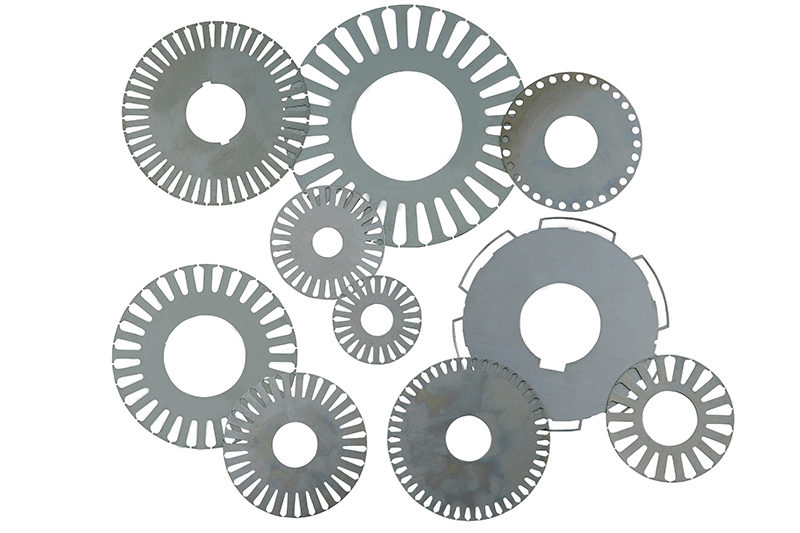

Besides raw material, we also provide value added processing services for electrical steel sheets and lamination, such as stamping sheets in shapes of UI, EI and customized shapes and sizes. Both CRGO and CRNGO electrical steel are available.

Punching line Annealing line

Silicon steel semi-final products

In addition, quotation for steel products could be based on EXW, FOB, CIF, DDP..., thoughtful shipping services could be provided based on needs.

Shunge Silicon Steel Domestic Sales Team will continuously make progress in providing customers with better products and service.

Silicon Steel Domestic Sales Team received award on Shunge Steel 15th anniversary

Read More

Why is lamination used in the core of a transformer?

Why is lamination used in the core of a transformer?

What is silicon steel stamping?

What is silicon steel stamping?

Shunge Silicon Steel Domestic Sales Team

Shunge Silicon Steel Domestic Sales Team