Why is lamination used in the core of a transformer?

Why is lamination used in the core of a transformer?

Oct 17, 2024

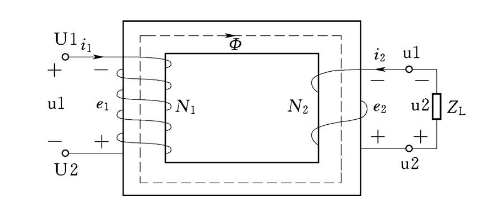

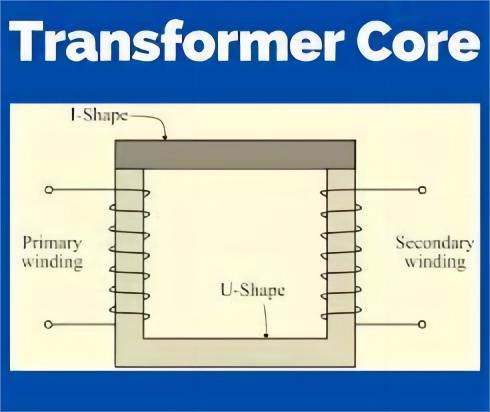

Transformers are electrical devices that transfer electrical energy between two or more circuits through electromagnetic induction. Transformers consist of two main components: a primary winding and a secondary winding, both wound around a core.

The transformer core of a transformer plays a crucial role in its efficient operation. It is typically made using laminations or stacked layers of a magnetic material, such as silicon steel. But why is lamination used in the core of a transformer? Let's delve deeper into this question.

The primary reason for using laminations in the transformer core is to minimize energy losses. When an alternating current (AC) flows through a transformer, the magnetic field generated by the current causes the core to undergo rapid magnetization and demagnetization cycles. These cycles lead to two types of energy losses in the transformer core: hysteresis loss and eddy current loss.

Hysteresis loss occurs due to the repeated flipping of magnetic domains within the core material, resulting in energy dissipation in the form of heat. Laminating the core helps to reduce this loss by segmenting the core into thin layers. These layers disrupt the continuous path for magnetic flux, reducing the area enclosed by the hysteresis loop and thus minimizing hysteresis loss.

Eddy current loss, on the other hand, is caused by the circulating currents induced within the core material due to the varying magnetic field. By using laminations, the transformer core is effectively divided into isolated pieces, reducing the continuous loops that the eddy currents can flow through. This segmentation significantly decreases the cross-sectional area available for eddy currents and, consequently, reduces eddy current losses.

Moreover, laminations also enhance the mechanical strength and stability of the transformer core. By stacking and tightly clamping the laminations together, the core becomes more rigid and less susceptible to mechanical stresses and vibrations. This ensures that the core maintains its integrity and optimal magnetic properties throughout the transformer's operation.

In summary, the use of laminations in the core of a transformer is essential for minimizing energy losses, particularly hysteresis and eddy current losses. By dividing the core into thin layers, laminations reduce the path for magnetic flux and circulating currents, resulting in improved efficiency and overall performance of the transformer. Additionally, laminations enhance the mechanical stability of the core. These factors collectively contribute to the reliable and efficient operation of transformers in applications.

Read More

Why is lamination used in the core of a transformer?

Why is lamination used in the core of a transformer?

How does a transformer achieve voltage transformation?

How does a transformer achieve voltage transformation?

What is a core in the transformer?

What is a core in the transformer?