What is silicon steel stamping?

What is silicon steel stamping?

Apr 10, 2023

The exceptional performance of cores relies on high-quality prime electrical steel raw materials and an advanced manufacturing system. Shunge Steel employs professional production lines equipped with precise high-speed mold punching machines to stamp the sheets, ensuring optimal results.

Electrical steel from leading or private steel mills

Through extensive testing and adjustments, we have achieved the capability to process stamping sheets within a thickness range of 0.1-1.0mm. Our cutting precision tolerance is tightly controlled, with a deviation of only ±0.01mm.

Customized steel sheet based on customer's drawing of design

Our mold punching process offers several advantages, including high guiding precision, stable punching performance, uniform blanking clearance, and extended service life.

To support our production needs, we currently operate 8 one-go punching machines and 10 high-speed punching machines. These machines, combined with rigorous quality checks, enable us to maintain high quality standards and ensure fast production lead times.

One-go punching production line

High-speed punching production line

Mature quality check system

Over time, we have established successful partnerships with nearly 200 motor companies. Our expertise lies in solving production and processing challenges that demand diverse product varieties, small-batch production, and customized non-standard sheet R&D.

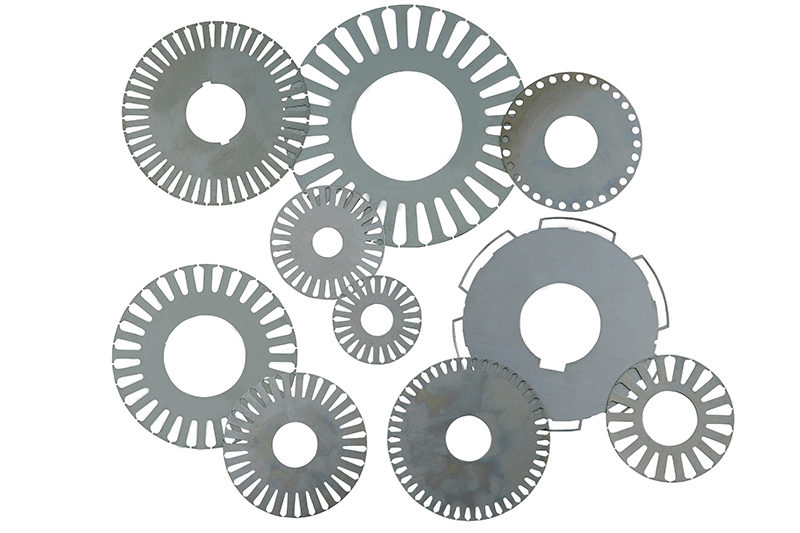

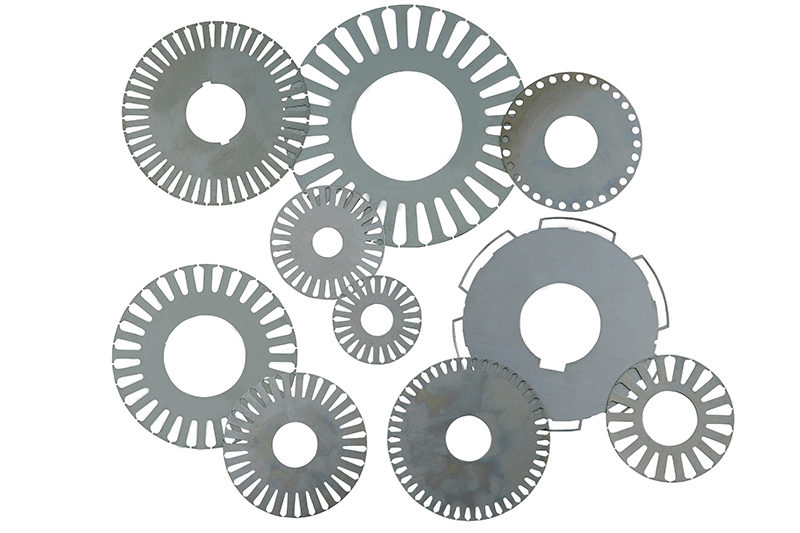

Regular stamping sheet product demonstration

If you would like to customize silicon steel sheet for own transformer core, motor core, stator and so on, it would be really helpful when more specifications and datas are provided:

Specification of material

Drawing of design

Required Quantity

Production technique

Production lead time

Required certificates of import

Read More

What is silicon steel stamping?

What is silicon steel stamping?