What is the Differences Between E-Type and C-Type Transformer Cores?

What is the Differences Between E-Type and C-Type Transformer Cores?

Apr 09, 2024

Transformers use various types of cores, with the most common ones being E-type and C-type cores. What are the differences between these two types of cores? And in which applications are they commonly used? Today, SHUNGE will tell you all about it.

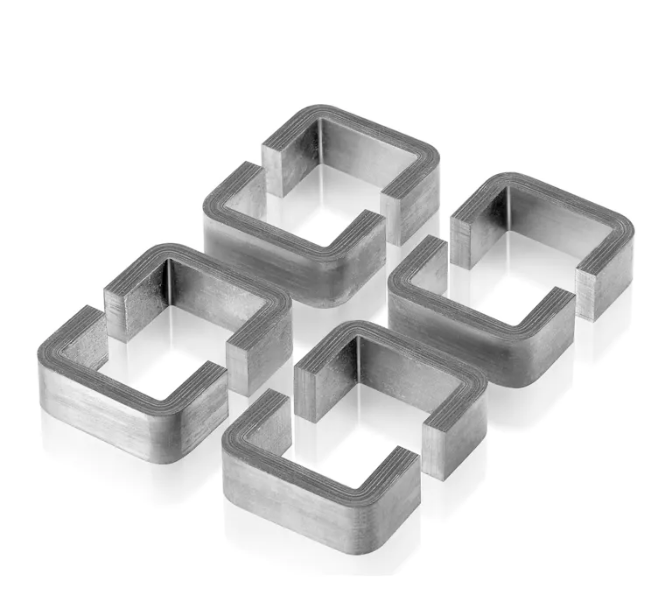

E-type and EI-type cores are widely used in the industry. One of their main advantages is that the primary and secondary windings can share the same core, resulting in a higher window utilization factor. The core also provides protection for the windings, making them less susceptible to mechanical damage. Additionally, E-type cores have a larger heat dissipation area and reduce magnetic field dispersion.

However, E-type cores also have some drawbacks. They tend to have larger magnetic resistance due to the presence of larger air gaps in the magnetic path, which reduces the overall performance of the magnetic circuit. Furthermore, E-type cores are prone to issues such as higher copper wire usage, greater leakage inductance, and susceptibility to external magnetic field interference.

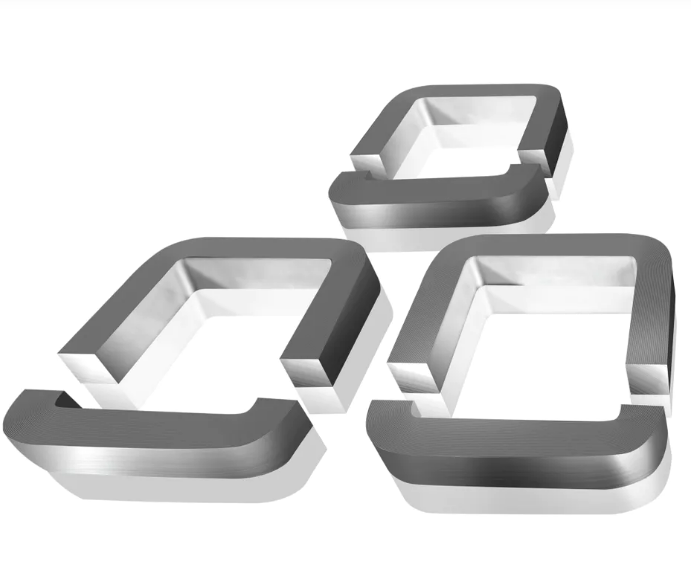

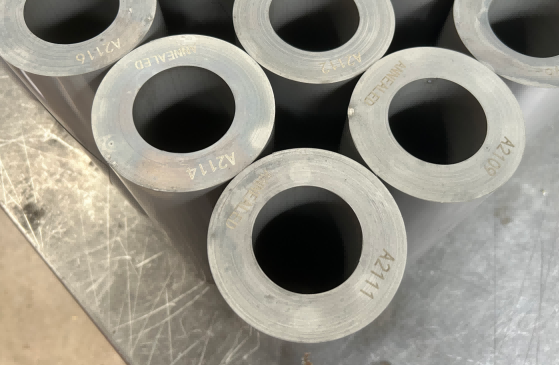

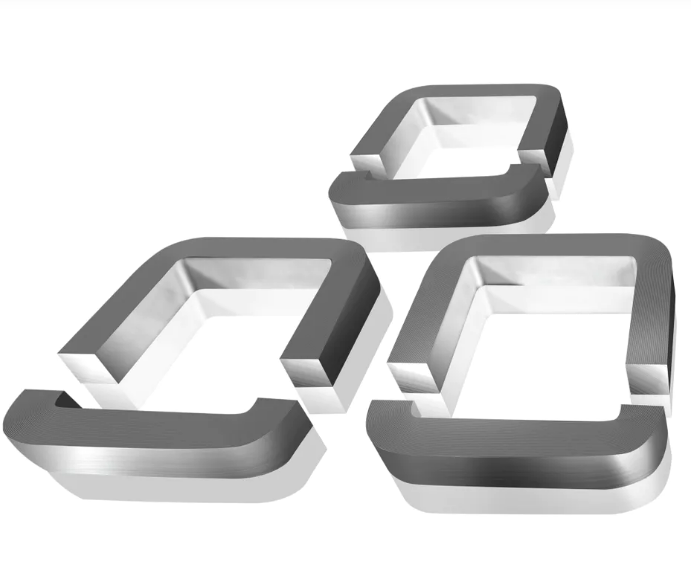

C-type cores are manufactured by winding cold-rolled silicon steel strips, which are then subjected to heat treatment and impregnation processes to form closed cores. These closed cores are then split to create two C-type cores. The windings are then encapsulated within the cores, and a pair of C-type cores are assembled and secured together to form the transformer.

C-type cores can have very small air gaps, and they offer advantages such as smaller size, lighter weight, and higher material utilization.

So, how can we identify the type of transformer core used in a power supply?

1. Identification based on appearance:

E-type cores have a shell-like structure, with a core that wraps around the coils. They are commonly made of high-quality silicon steel sheets such as D41 and D42. C-type cores, on the other hand, are made of cold-rolled silicon steel strips and have a core-type structure.

2. Identification based on the number of winding terminals:

Power transformers often have two windings, a primary and a secondary, resulting in four terminal connections. Some power transformers may have an additional shielding layer between the primary and secondary windings for AC noise and interference suppression. In such cases, the shielding layer is grounded. Therefore, power transformers typically have at least four terminal connections.

3. Identification based on the stacking method of silicon steel sheets:

In E-type power transformers, the silicon steel sheets are interleaved, with no air gaps between the E-shaped and I-shaped sheets. The entire core fits together tightly. In contrast, audio input/output transformers have certain gaps between their E-shaped sheets, which serves as a distinguishing feature from power transformers. C-type transformers are generally used as power transformers.

Shunge Steel, founded in 2008 and headquartered in Lecong, Foshan, produces cores with features such as low iron loss, high magnetic permeability, and high saturation induction. Our cores find applications in various fields, including signal communication, power drive, traction, renewable resources, charging station power control, high-precision measurement and control, new energy vehicle battery management, power control, welding, and new energy vehicle motor control.

If you have any core requirements, please feel free to contact us.

Read More

Why is lamination used in the core of a transformer?

Why is lamination used in the core of a transformer?

The Significance of Lamination in Transformer Cores

The Significance of Lamination in Transformer Cores

CD Core: Enhancing Transformer Performance with Cutting-Edge Technology

CD Core: Enhancing Transformer Performance with Cutting-Edge Technology

Transformer Cores: Enhancing Efficiency and Performance with Silicon Steel

Transformer Cores: Enhancing Efficiency and Performance with Silicon Steel

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

Transformative Core Materials: CRGO & CRNGO for Optimal Performance in Transformers

What are the characteristics of transformer laminated core?

What are the characteristics of transformer laminated core?

What is the Differences Between E-Type and C-Type Transformer Cores?

What is the Differences Between E-Type and C-Type Transformer Cores?

TEN differences between dry-type transformers and oil-immersed transformers

TEN differences between dry-type transformers and oil-immersed transformers

Why Transformer Cores Use Silicon Steel Laminations

Why Transformer Cores Use Silicon Steel Laminations

What is the difference between adding or not adding an iron core to the transformer?

What is the difference between adding or not adding an iron core to the transformer?

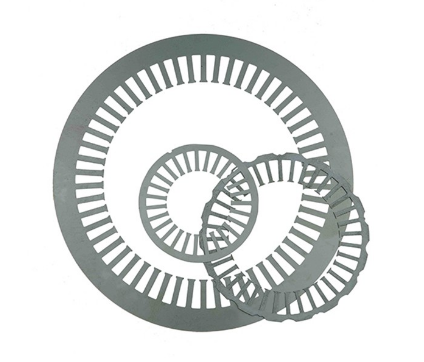

What impact does steel lamination punching have on motor performance?

What impact does steel lamination punching have on motor performance?

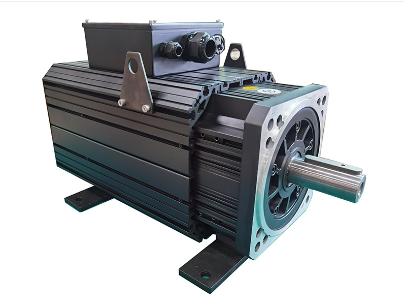

How does a servo motor work?

How does a servo motor work?