Is Silicon Steel Strong?

Oct 27, 2025

Regarding "Is silicon steel strong?" In simple terms, the "strong" of silicon steel is more reflected in its electromagnetic properties rather than the mechanical strength against impact as we usually understand it. As a functional material, its mechanical strength is sufficient to meet the processing and usage requirements for its specific purpose, but it is not the core of its design.

The "strong" degree of silicon steel in different dimensions:

Mechanical strength (tensile and impact resistance) : In terms of tensile and impact resistance, silicon steel performs moderately weak. Its tensile strength is typically between 370 and 540MPa, which is higher than that of ordinary plastics but far lower than that of specialized structural steels (such as high-strength steel, which can reach over 1000MPa).

Electromagnetic performance "strength" (iron loss, magnetic induction) : In terms of iron loss and magnetic induction, silicon steel demonstrates extremely "strong" and outstanding performance, which is the core value of silicon steel. Low iron loss means high energy conversion efficiency and less heat generation. High magnetic induction can make electrical equipment smaller in size and lighter in weight.

Process performance (adaptability to stamping, shearing and other processing) : In this aspect, silicon steel performs quite well. Silicon steel has certain plasticity, toughness and surface flatness, which can meet the requirements of stamping, shearing and lamination of motor and transformer cores.

A Deep Understanding of the "strong" in Silicon Steel

From the above information, it can be seen that to evaluate whether silicon steel is "strong", it is necessary to combine specific scenarios.

The core advantage lies in the "high efficiency" and "energy conservation" of electromagnetic performance: The "strength" of silicon steel is mainly reflected in its soft magnetic properties. In an alternating magnetic field, it needs to be easily magnetized and demagnetized, while the energy it consumes (i.e., iron loss) should be as low as possible. This is directly related to the efficiency of transformers and motors. According to statistics, upgrading existing transformers with high-end silicon steel saves nearly as much electricity in a year as the power generation of the Three Gorges Power Station, which shows its significant "strong" contribution in terms of energy conservation.

Mechanical strength is based on the premise of meeting processing and usage requirements: The mechanical strength of silicon steel fully serves its function. Excessive strength or hardness can lead to difficulties in blanking and rapid wear of the die. However, if the strength is too low, it may not be able to ensure that the core maintains structural stability in a high-speed rotating motor. Therefore, its strength is controlled within an appropriate range, capable of withstanding electromagnetic force, centrifugal force and stacking pressure, while also facilitating large-scale and high-precision stamping processing.

The "weak link" to note: Although the overall strength is sufficient, silicon steel, especially cold-rolled silicon steel, is relatively sensitive to processing stress. Shearing, bending and other processing can cause stress and strain to be generated inside the material, which may deteriorate its magnetic properties to a certain extent. Therefore, in some situations with extremely high performance requirements, the completed iron core may need to undergo annealing treatment to eliminate these stresses and restore its best electromagnetic performance.

Read More

Selecting of steel

Selecting of steel

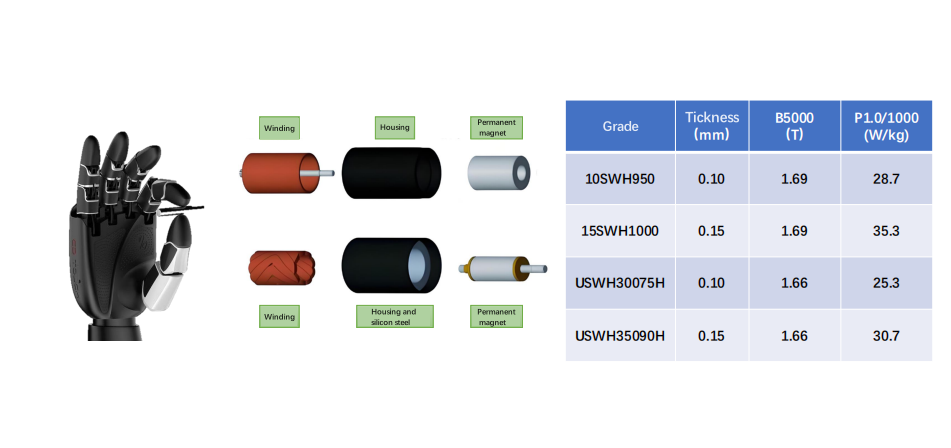

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Application of ultra-thin silicon steel (0.1-0.2mm) in new energy vehicles

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Applications of ultra-thin silicon steel (0.1-0.2mm) in the field of humanoid robots

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

Advantages and applications of self-adhesive coating technology for ultra-thin silicon steel.

What are the advantages of using ultra-thin silicon steel in axial cores

What are the advantages of using ultra-thin silicon steel in axial cores

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

In which fields is ultra-thin silicon steel (0.1-0.2mm) used

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

What are the advantages of ultra-thin silicon steel (0.1-0.2mm)?

Why Pursue "Ultra-thin" Silicon Steel?

Why Pursue "Ultra-thin" Silicon Steel?

Why pursue ultra-thin non-oriented silicon steel?What are the key advantages of this design?

Why pursue ultra-thin non-oriented silicon steel?What are the key advantages of this design?

Why choose ultra-thin non-oriented electrical steel?

Why choose ultra-thin non-oriented electrical steel?